With a wide range of production capabilities, France-based

Erpro Group is able to adapt to the needs of its customers by offering them a range of services, from prototypes, through pre-production to mass production.

In this fast-moving environment, Workplan and WorkNC software supplied by

Hexagon’s Manufacturing Intelligence division, play a key role.

Since it was formed in 1997, Erpro has pioneered the use of new production methods. It acquired an additive manufacturing (AM) machine equipped with selective laser sintering (SLS) technology — an AM process that belongs to the powder bed fusion family. “Erpro has made AM part of its DNA,” said Cyrille Vue, the holding company’s director.

The Erpro Group comprises six companies: Erpro, a prototyping specialist; Sprint, a metal AM, plastic injection and machining firm; 3D Nord Factory, a small series plastic moulding manufacturer; Dpn, aplastic injection specialist; Silinov, a manufacturer of silicone parts in 3-D and by moulding; and Erpro 3D Factory, a start-up company focused on large-scale AM.

The Group uses Workplan production planning software to automate and manage processes such as job costing, quotations, sales order processing, planning, quality, time, purchasing and stock management.

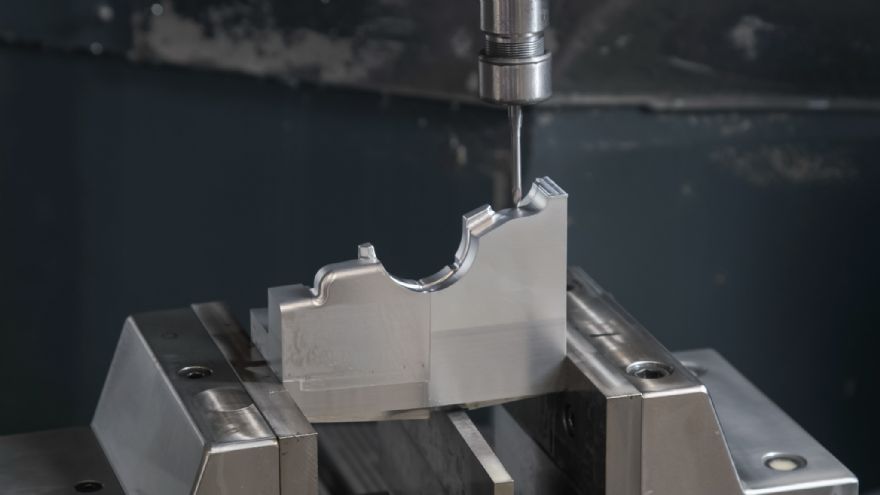

Workshops in a number of companies throughout the Group also use WorkNC, Hexagon’s automatic CNC software for surface and solid models in mould, die and tooling businesses for two- to five-axis CNC programming.

From its inception to present day, the Erpro Group, which has a facility in Saint-Leu-la-Forêt, has not stopped developing. It has a wide range of machines enabling it to offer various services to its customers, such as additive manufacturing (AM), machining, silicone moulding, RIM moulding, plastic injection and paint finishing.

The synergy of these processes enables the company to produce prototypes, pre-series and large series, with materials ranging from metal to plastic. A good example of this capacity is 18 million eyelash brushes, manufactured by the start-up Erpro 3-D Factory, which were delivered to luxury cosmetics brand Chanel in two years.

Digital threadThe essence of 3-D printing is digital — an object is designed in 3-D then a toolpath is generated and used to manufacture it after its transformation into ISO programs by the post processor corresponding to the machine. In addition to the digital thread for manufacturing, there is also the thread for the management system.

Mr Vue added: “We abandoned the first enterprise resource planning (ERP) system we had acquired because it was not suited to our needs. A new contract we were tendering for required simplicity, speed, agility and flexibility from the future software package.

“At the end of our comparison of various systems on the market, we chose the Workplan software from Hexagon.”

Implementing Workplan was simple, and easily adopted by all employees in the departments using it: sales, quality, production, sales administration, etc. The speed of Workplan’s operation can be measured in a few clicks, such as the conversion of a quotation into an order, then into an order form to the relevant department.

Its agility is put to the test every day thanks to its ability to accompany clients right up to the launch of the manufacture of their products. For example, an order for 100 green cups can be changed in a few clicks to an order for 25 magenta, 25 yellow, 25 cyan and 25 black.

Flexibility is also important: a delivery can be distributed differently from initially planned, just before it leaves.

Mr Vue continued: “The flow of information in Workplan must be continuous and precise. This is particularly important when we are looking at the profitability of an operation. In this respect, WORKPLAN has fully supported the growth of Erpro Group, acting as its production planning backbone.”

WorkNC comes into its ownThe Erpro Group has also invested in Hexagon’s WorkNC CAM software, which now plays an important role in the workshops, particularly on the Erpro site. Mr Vue explained: “With WorkNC, we are able to machine a 3-D printed part on a five-axis machining centre, from the same CAD file.” This is where WorkNC comes into its own, as there are new parts to be manufactured every day, all of which require new programs to be created.

Specialising in thermoplastic injection, from prototypes to small series, Erpro subsidiary Dpn works mainly in the automotive sector. From design through to the manufacture of the finished product, Dpn assists companies in carrying out their projects. As a market leader for more than 20 years, Dpn is regarded by car manufacturers and equipment suppliers as a “go to” mould maker.

The company has now integrated Workplan to optimise and organise its production cycle in order to offer what the company describes as “an excellent level of service”.

Pascal Renoud, director of the Dpn plant in Tremblay-en-France, said: "WorkNC also plays a part in programming machining toolpaths to reduce cycle time, freeing up the machines much quicker, ready for the next job.

“After being checked and validated, the moulds that come out of the machining process can be used to produce complex thermoplastic parts in all types of plastic, including PEEK, which is widely used in the aeronautics industry, thanks to its mechanical characteristics and resistance to high temperatures."

Workplan serves as a guideline in their production processes, and is also a valuable working tool for the sales administration. It manages both the digital and physical flows once the tender has been won.

Mr Renoud concluded: “Workplan allows us to monitor the progress of the project in real time and to produce a business report to assess its profitability. This database is invaluable for similar projects in the consultation process, allowing us to rectify our estimates if necessary, in a very quick, reactive manner."