While bicycles are a long-established mode of transport, that does not mean they have not evolved with the times. Having built bikes in Wisconsin since 1976,

Trek Bicycle has moved with the times, as evidenced by the company’s investments in manufacturing technology — including tooling systems from BIG Kaiser that are supplied and supported in the UK through Tamworth-based

Industrial Tooling Corporation Ltd.

Trek has been on the forefront of the electric bike movement and equipment advances for cycling, such as lights, computers and sensors. The company is also a manufacturer and distributor under the brand names Trek, Electra Bicycle Co, Bontrager, and Diamant Bikes — products that are marketed through 1,700 independently owned bicycle shops across North America, subsidiaries in Europe, Asia, South Africa — plus distributors in 90 countries worldwide.

Every idea a Trek engineer has for a new technology or how to integrate it, is passed to the company’s Prototype Development Lab. This is where the likes of frames and accessories are experimented with and machined to make Trek’s ‘most innovative ideas come to life’.

Cory Marty, a senior engineering technician at Trek’s Prototype Development Lab, said: “Every time we run a part, it’s something new that we have just programmed. Our turnround time, from when an engineer puts in a project to the time they have something in their hands, is usually about 10-14 days.

“We don’t get the luxury of setting up an old job or running multiples of anything. A lot of the work we do is with tight, deep pockets with ‘stickouts’ in the range 6 to 8xD. Every part is a first-off, and all are 3D-surfaced organic shapes.”

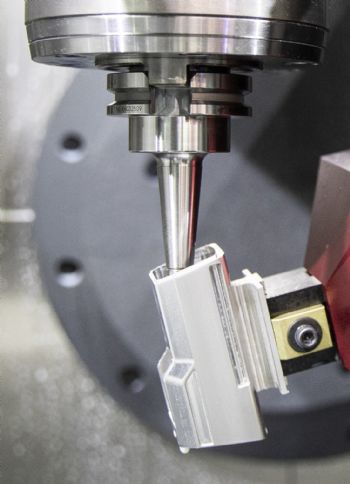

Rigidity and powerWhen Trek recently bought a five-axis machining centre, Mr Marty knew he would have to invest in new tooling that would enable him to get the best out of the machine. Due to the need for cutting deep pockets, Mr Marty realised he needed more than rigidity and high-power cutting.

With its CAM software, Trek could program a three-axis tool-path that recognised when the tool would collide with the model. The software would then automatically start tilting the tool axis out of the way to achieve tool-holder clearance, but with standard ER 32 or ER 16 tool-holders in a deep and tight pocket, the machine had to tilt significantly to clear the body of the holder, resulting in unnecessary axis movements or potential machine collisions.

“Every time we added an extra extension or cobbled something together, we knew we would be adding runout. We were looking for tooling that was similar to shrink-fit holders, with the shape and accessibility you could get, but we weren’t ready to step up to a full $30,000 shrink-fit package that limited us to one or two diameters.”

Considering the work the lab does, the easy changeover was also of particular importance. Mr Marty says he has to set up 10 to 15 tools, changing tool lengths each time for each part Trek works on, adding that the heating and cooling cycles involved with shrink-fit tools would “simply be too time-consuming”.

After browsing tooling catalogues in search of holders that could be quick and easy to handle and with dimensions that would allow access to tricky pockets, Mr Marty invited Mark Sazy from BIG Kaiser to demonstrate the company’s MEGA Micro Chuck.

These feature a narrow body, with nut diameters ‘as slim as’ 10mm and a shallower taper angle that ‘boosts the holder’s rigidity and limits the extreme angles needed to reach down into deeper pockets’.

Meeting requirementsMr Sazy said: “MEGA Micro Chucks were designed for the exact scenario Mr Marty was dealing with in the prototype lab. The prototyping lab is a place where everything is ‘under a microscope’ and all eyes are on the details. It was great to have the opportunity to demonstrate our tools under those conditions.”

Mr Marty decided to purchase a package of 15 MEGA Micro Chucks to use with all of Trek’s cutters that are 6.35mm and under in diameter. “The MEGA Micro Chucks have the same profiles and shapes of shrink-fit holders while offering the versatility of collets. You can use any size shank you want. They’re balanced a lot better than the ER 32s that we were running previously, so they don’t vibrate as much.

“The extreme tilts the programming software once had to adjust for have been eliminated. I would say that some 50% of our reach issues were resolved just by changing holders without manually changing the way things are programmed. The machine only has to tilt maybe 10deg out of the way to get down into the pockets. We are able to reach into places we weren’t before without extravagant, cobbled-together extensions, and with higher speeds and feeds — and better finishes.”

Mr Marty said shrink-fit holders have their advantages, and, as with every machine shop, the cost or time required for the perfect solution isn’t always an option. He knew exactly what he needed, and through research and trial found the BIG Kaiser alternative was what he needed.