Hexagon’s Manufacturing Intelligence

Hexagon’s Manufacturing Intelligence, a global leader in ‘digital reality solutions’ that combine sensor, software and autonomous technologies, has demonstrated how ‘innovation can be accelerated’ by opening up the possibility of completing complex CFD (computational fluid dynamics) simulations that were previously too time-consuming and expensive, by using technology from Fugaku — the world’s fastest supercomputer.

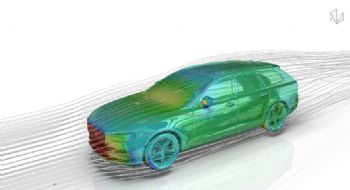

The company’s Manufacturing Intelligence division has shown that the performance of next-generation aircraft and electric vehicles can be explored in greater detail and with many more iterations using the power of simulation.

Also, that by using cutting-edge semiconductors, manufacturers can analyse “all the complexities of reality with less than half the energy use and at a fraction of the cost of traditional simulation methods”.

CFD simulations require significant computational power and resource, necessitating engineers having to spend many hours simplifying a real product design just so that it can be simulated to make sure it will perform as needed.

In some instances, 90% of an engineer’s time can be dedicated to this manual process, and engineers are increasingly being challenged to ‘scale-up’ simulations to manage more elements.

As a result, the cost and time to achieve these simulations is prohibitive and engineers can only simulate an approximation of a product. However, Hexagon’s ‘Cradle CFD’ customers will now have the opportunity to tap into the power of the ARM-based Fugaku computer architecture to achieve complex simulations quickly and easily — thanks to a new partnership that will allow customers to use Cradle CFD software on Fujitsu’s commercially available supercomputer PrimeHPC.

This uses Fugaku technology and will enable customers to quickly explore multiple design options, using frequent simulations to refine and test their designs and explore new concepts that cannot currently be explored with physical testing or simulation.

Tomohiro Irie, director of R&D at Cradle CFD, said: “By using the computing power of Fugaku with our simulation tools, we will encourage users to simulate phenomena that simply weren’t feasible before due to the computation time and cost.

“Because Cradle CFD is used in diverse applications, I expect that these technical developments will contribute to making the power of Fugaku more accessible for general use.”