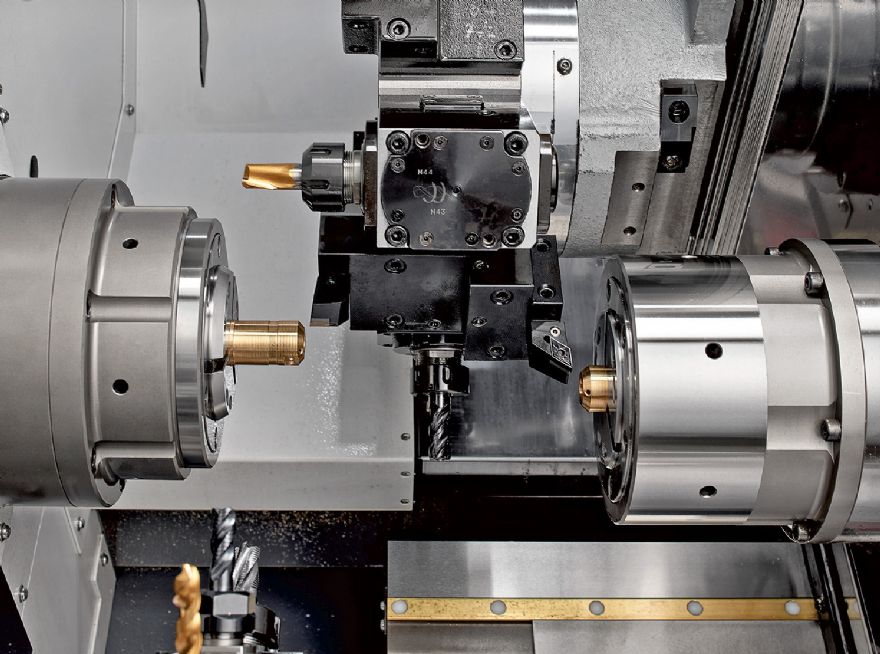

Machining area of Citizen's Miyano BNE‐65MYY fixed head lathe

Machining area of Citizen's Miyano BNE‐65MYY fixed head latheBushey-based

Citizen Machinery UK Ltd’s LFV (low frequency vibration) chip-breaking software, which forms part of the operating system in the controls on some of the manufacturer’s sliding-head and fixed-head mill-turn centres, will feature strongly at

MACH 2022 (Hall 20, Stand 150), as this year marks the fifth anniversary of the technology’s launch.

The principle of operation “is distinct from, and superior to, pecking macros programmed into individual machining cycles”. The patented system is gradually being incorporated throughout the company’s Cincom sliding-head lathes, initially on the main spindle and more recently also on the sub-spindle.

There will be five Cincom machines equipped with LFV on show at

MACH 2022. A pair of Citizen’s Miyano fixed head lathes also benefits from the technology, one of which will also be on display. The chip-breaking function can be switched on and off by G-code during a cycle, as required, as if it were part of the program.

The size of the actual chips can also be predetermined, as close control is maintained over the relationship between spindle speed and LFV oscillation of the tool by tens of microns, which has the effect of repeatedly retracting the tool tip clear of the workpiece and allowing coolant to penetrate the cut more efficiently.

Tool life is extended, surface finish is improved, and stringy swarf — along with the need for manual swarf clearance — is therefore ‘a thing of the past’. Three modes of LFV may be selected for machining with static and driven tools.

A total of 12 bar-fed sliding-head and fixed-head mill-turn centres will be demonstrated under power by Citizen Machinery UK, including an automated production cell with integrated loading and unloading. Making its world debut will be the new, 20mm bar capacity Cincom L20-XIIB5LFV.

An upgrade of the Cincom L20, Citizen’s best-selling sliding-head lathe, it features simultaneous five-axis control via the improved, super-fast M850VM CNC with 15in touchscreen and allows multi-axis programming for superimposed machining with up to three tools in cut at the same time; and with the swivel range of the B axis increased to 110deg, more complex machining to higher accuracy at the main spindle can be achieved.

Other improvements include: a larger pitch between adjacent tools on the opposing and back tool posts to facilitate setting and reduce set-up time; a higher specification sub-spindle for improved productivity; and the ability for LFV to be used when reverse-end machining.

Making its

MACH debut is a Series-5 Cincom M32-VIIILFV, which will be demonstrated alongside a fixed-head Miyano BNE‐65MYY. Both have been redesigned to offer more power and flexibility and have been fitted with the latest Mitsubishi 800-series touchscreen control.

Consequently, the latter machine is Citizen’s first 65mm-capacity lathe to offer super-imposed machining, which allows three tools to be in cut together under simultaneous five-axis control. Also on show for the first time will be a Cincom L32‐XLFV with integrated, high-speed laser cutting, a capability that was originally developed for efficient production of apertures in thin-wall stents on smaller Citizen sliding-head lathes.

Also be exhibited for the first time at MACH will be a Cincom D25-VIILFV with the proprietary chip-breaking software. As on many other sliding head lathes manufactured by Citizen, the user has the advantage of being able to remove the guide bush for more economical material usage when producing shorter components — typically up to 2.5-times the bar diameter.

A further highlight will be a Cincom A20‐VIILFV, the first Citizen lathe to be equipped with multi-axis LFV software in a Fanuc-based Cincom control dedicated to this machine model. The exhibition will also feature the first showing at a national exhibition in the UK of the 12mm bar capacity Cincom L12-XLFV; this offers five rear-facing static and driven end-working tool positions and the addition of a Y axis on the counter spindle to mirror the main spindle’s three axis movements. The machine is intended primarily for producing dental abutments and implants, as well as other complex components.

From the Miyano stable, the ABX-64THY with 80mm bar capacity and an ANX-42SYYLFV with Fanuc control will also make their debuts at a national show in the UK. Making another appearance at MACH to illustrate automated chucking will be the twin-spindle Miyano GN-3200W equipped with a high-speed loader for high levels of productivity.

The compact, rigid and thermally symmetrical machine offers a wide choice of infeed/outfeed devices, single or double high-speed gantry loaders, and transfer and turnover units — allowing the GN-3200W to undertake automated production.