Visitors to the stand of Worcestershire-based

REM Systems Ltd at

MACH 2022 (Hall 20, Stand 338) will see automation solutions designed to suit a wide variety of applications. The event will take place from 4-8 April at the NEC, Birmingham.

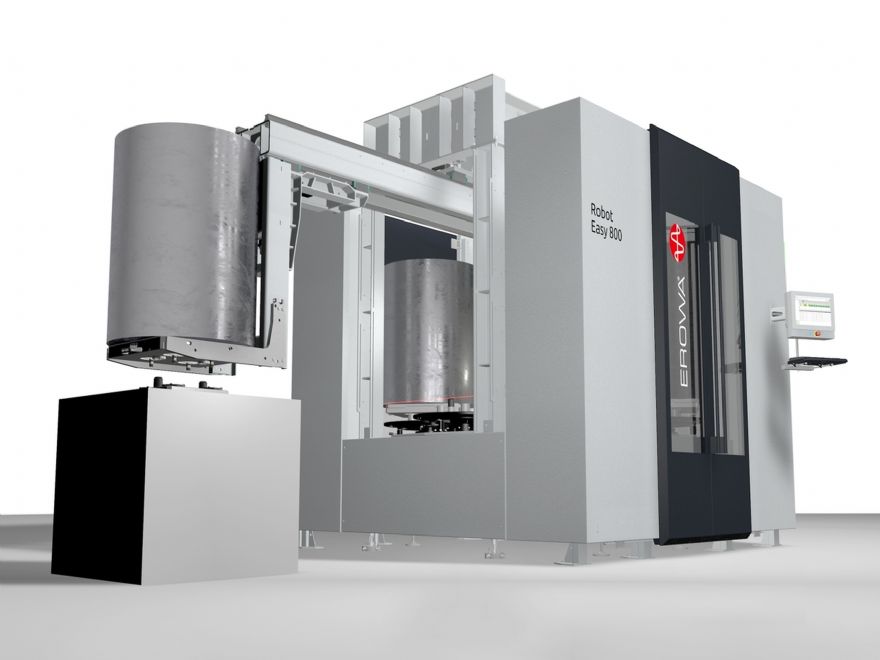

On show will be Erowa’s best-selling Robot Compact 80, a Robot Easy 800 and an example of the Erowa LoadMaster range, which can be specified for parts up to 4,000kg.

Managing director Ian Holbeche said: “In today’s globally competitive arena, manufacturers must take every opportunity to improve efficiency and productivity, getting the most out of their machine tools and extending operational hours.

“With over three decades of automation experience, Erowa has developed a range of robots for every budget and just about every size of workpiece.”

With an optimal ratio between a large number of magazine positions and a small amount of floor space required, the Erowa Robot Compact 80 is the company’s best-selling automation solution.

With a transfer weight capacity of up to 80kg, it can serve one or two machine tools, and move up to 11 different Erowa pallet sizes for varying workpieces — plus the magazine levels can be set precisely to meet requirements.

The Robot Easy 800 offers a compact design that is ‘highly configurable’ and able to transfer parts up to 800kg, allowing CNC machine tools to be configured as automated manufacturing cells at reasonable cost.

Using the Erowa MTS 400 pallet system in the magazine, up to 12 stations can be loaded with parts. The transfer arm is fitted with a fork gripper and has a reach of 2m from the outer edge of the robot, leaving enough space for manual set up of the machine if required.

Capable of transferring parts between 500 and 4,000kg the LoadMaster uses a ‘kinematic 360deg swivel function’ that allows the robot to access machine tool tables and store workpieces — on up to four levels and within a compact footprint.

Loading and setting stations are an integral part of the cell and are designed to make the adding and removal of components as easy as possible. Supporting the range of robots will be podiums featuring the Erowa ranges of MTS-CleverClamp and Spindle-UPC-PC210 tooling.

Meanwhile, Erowa’s UPC-PC210 universal power chuck offers ‘workpiece stability’ with a holding force of 30kN and clamping accuracy with a repeatability of 2µm.

Mr Holbeche added: “We are looking forward to welcoming visitors to our stand to see our systems in action, and to explaining Erowa’s four-step productivity plan that is designed to improve productivity and efficiency by harnessing the ‘dead’ time many companies do not use to the full potential.”