Gloucester-based

the Sempre Group Ltd, an industrial metrology specialist, will demonstrate how its technology can streamline an entire manufacturing process from the preparation of components to electronic reporting at

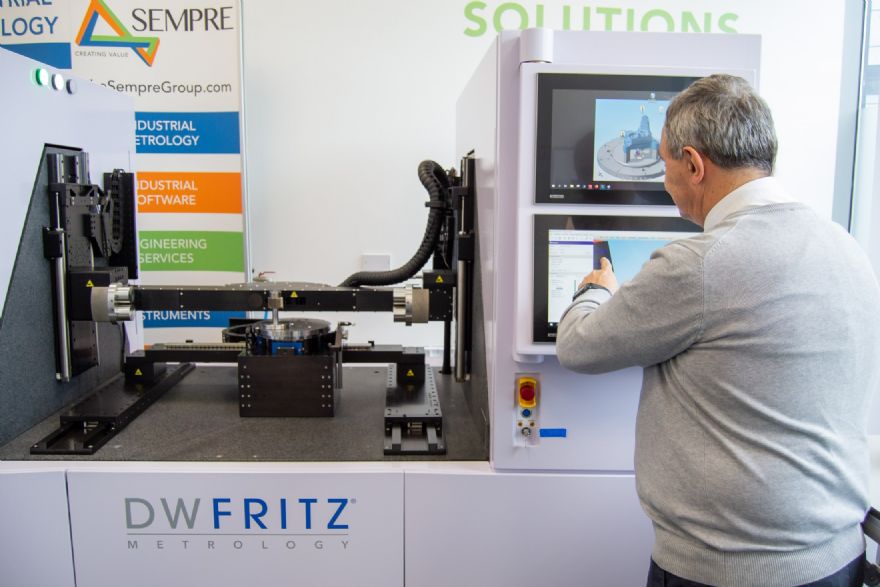

MACH 2022 (Hall 17, Stand 400). At the event, taking place 4-8 April at the NEC, Birmingham, the company will be showcasing its current portfolio and its latest technologies, including the DWFritz ZeroTouch 3-D scanning system.

The Group will also demonstrate how manufacturers can harness Quality 4.0 to improve their productivity, which begins at the preparation stage and involves using automated solutions to automatically balloon and populate inspection reports such as First Article Inspection Reports (FAIRs).

From there, manufacturers can develop measurement routines and minimise manual inspections, enabling them to focus on process improvements. Augmented reality (AR) tools can then guide operators through the assembly process and reduce errors by projecting instructions for them to follow.

After assembly, manufacturers can bring all their data together in one electronic quality management system (QMS), automating their data collection and creating a single digital thread for a part’s entire manufacturing history.

On the stand, the Sempre team will illustrate how manufacturers can use technology at each of these stages, including ballooning, creating in-process inspection plans and providing bespoke solutions like fixtures and connected metrology.

To help start the quality process, it will feature the High QA Inspection Manager automated QMS software, which allows users to scan entire drawings and extract the geometric dimensioning and tolerance (GD&T) data. Engineers can also import inspected results from any coordinate-measuring machine (CMM) or vision measurement machine (VMM).

For those visitors that have completed the ballooning process, Sempre will also be highlighting, for the first time at an event in the UK, its latest metrology systems including the DWFritz ZeroTouch 3-D scanning system, Novacam non-contact bore inspection equipment and the Sensofar S neox and S Wide optical profilers.

Quality, efficiency and yieldMike John, technical director of The Sempre Group, said: “Quality, efficiency and yield just aren’t given the attention they need, which is why Britain’s manufacturing productivity lags behind major competitors like the USA and France.

“Our mission is to change the quality narrative, and at

MACH 2022 we will demonstrate how metrology can help manufacturers gain insight into processes and make more informed decisions that will increase productivity.

“Quality begins with ballooning and transcends the inspection process through to a part’s assembly and compliance reporting, added John. “On the stand, our team will show how applying these different technologies can provide a holistic solution to improve efficiency, reduce scrap and create a product to specific tolerances that can be reported on.”

Also on the stand will be Jenoptik’s Opticline T3D with tactile 3-D measuring probe, the Waveline W800 and CS305 optical shaft measuring system. It will also feature the Micro-Vu Excel and Vertex optical CMM systems, which can deliver precise measurements without coming into contact with the part.