Nottingham-based

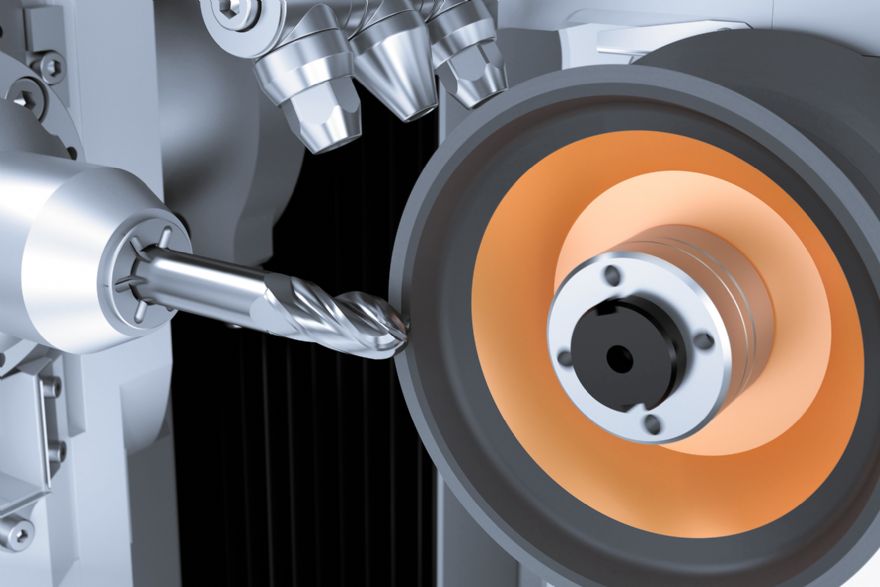

Vollmer (UK) Ltd will be giving a UK show debut to its VGrind 360S grinding machine at

MACH 2022 (Hall 20, Stand 550), which is taking place from 4-8 April at the NEC, Birmingham.

The machine, which is designed for the complete machining of solid-carbide cutting tools, will be shown alongside a Vollmer CHX/HS and a Vollmer Loroch Powerstar — machines for sharpening circular saw blades.

The VGrind 360S five-axis CNC grinding machine can be used to manufacture carbide drills and milling cutters up to 25.4mm in diameter, although Vollmer says that “depending on the machine kinematics and the tipping of the grinding wheel packages, tools with diameters of up to 100mm are also possible.”

Features of this machine include linear induction motor and linear slides on the X, Y and Z axes for ‘enhanced kinematics, improved precision and higher surface quality on the cutting tool’; and while users can access the control panel comfortably while having full visibility of the work envelope, a multi-function handwheel that can be freely positioned allows the setting of a required axis without using the control panel.

On the VGrind 360S, the vertical double-spindle concept, which has been proven on previous machines, now features ‘spindle indexing’, which always stops the spindle at a specific position, resulting ‘a reduction of axial run-out errors and concentricity issues while offsetting wear in the HSK holding system’. Another feature is a heat exchanger that cools motors and spindles for increased thermal stability.

Options for automated operation include the HP 160 pallet magazine for up to 900 tools, the HPR 250 free-arm robot for the automatic machining of tools with various shaft diameters, and the HC 4 chain magazine; this has space for 39 HSK-63A tools or up to 158 shank-type tools.

Automation also extends to an eight-tool grinding-wheel changer that ensures the correct grinding wheel is selected for the job at hand with no manual intervention.