Nottingham-based

Vollmer UK Ltd will be demonstrating circular saw blade production at

MACH 2022 (Hall 20, Stand 550), which is taking place from 4-8 April at the NEC, Birmingham.

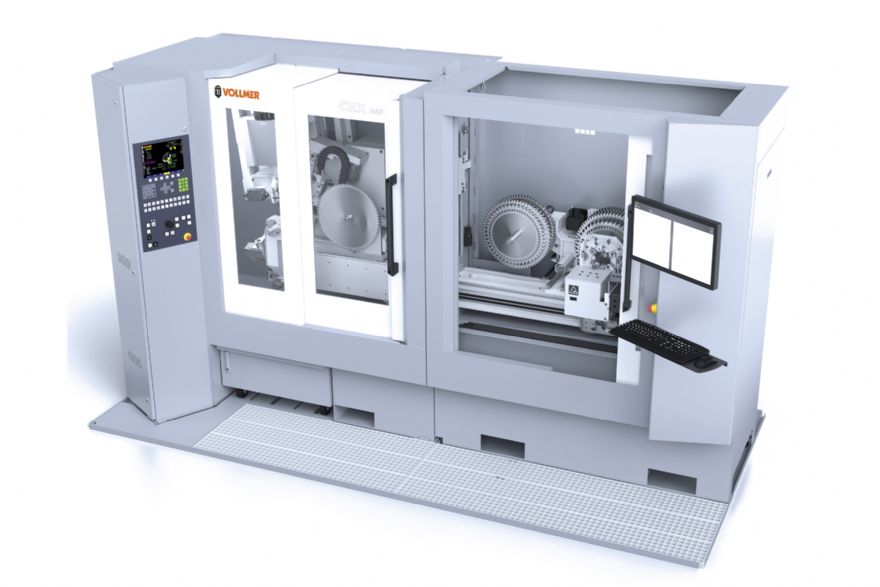

Taking centre stage will be a Vollmer CHX/HS CNC grinding machine and a Loroch Powerstar 850; these will be exhibited alongside a Vollmer Vgrind 360S tool-grinding machine designed for carbide and PCD rotary tooling.

The CHX/HS automated CNC machine can sharpen the tooth face and top of circular saw blades in a single set-up with continuous unmanned running.

This machine is available in two variants, the CHX840 and the CHX1300 for carbide-tipped circular saw blades with diameters up to 840 or 1,300mm respectively; and with five CNC axes, the CHX/HS can machine saw blades with all common tooth geometries.

The CHX machine at

MACH 2022 will be connected to Vollmer’s HS automation solution (hence the CHX/HS designation); this provides automatic loading of the CHX machine for some 7hr of unmanned operation. Moreover, the programming and preparation of the saw blade stack can be undertaken during machine operation.

Meanwhile, the Vollmer Loroch Powerstar 850, which is designed to simplifiy the production of metal-cutting saw blades, can undertake the sharpening, re-toothing and chamfering of saw blades. This CNC high-tech grinding machine provides semi-automatic chamfering of the saw blade and an adjustable chamfer angle; it also has an attachment for cutting-in chip-breaker grooves.

Vollmer says the machine is ideal for any small to medium-size business involved in the grinding of metal-cutting saw blades as it can process HSS saws, solid-carbide saws and friction saw blades from 130 to 850mm in diameter with blade thicknesses up to 8mm and up to 998 teeth.

The machine incorporates a 19in touchscreen CNC that enables blades to be programmed in minutes with data inputted directly at the machine via the colour display that is ‘comparable to a Smartphone configuration’. The Loroch Powerstar 850 has a powerful direct-drive grinding wheel configuration that ‘reduces power loss and eliminates undesired vibration that can impact blade quality’.