Leamington Spa-based

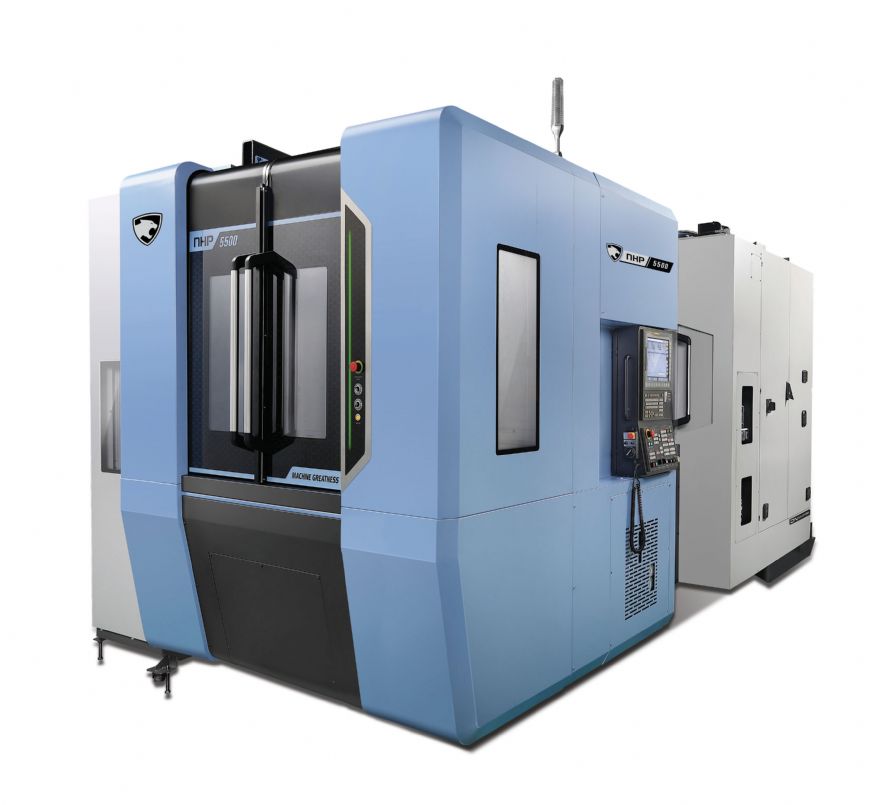

Mills CNC, the exclusive distributor of DN Solutions’ machine tools in the UK and Ireland, has just launched the NHP 5500, a ‘next-generation’ high-productivity horizontal machining centre.

The twin-pallet machine represents a significant upgrade on its predecessor, and boasts faster acceleration/deceleration rates (X/Y/Z = 0.91G/1.07G/1.02G), impressive 60m/min rapid rates, improved tool change times, enhanced thermal compensation and faster B-axis table rotation. The machine also comes equipped with a generous-size servo-driven ATC (from 40 up to 376 tools depending on the tool magazine selected), tool change times are 1.7sec (T-T-T) and 4.7sec (C-T-C).

The NHP 5500 is equipped with a built-in 37kW 10,000rev/min BT50 spindle with integrated smart thermal compensation sensor technology. This, combined with the machine’s advanced oil-cooled spindle system, reduces thermal displacement and ensures that high-part accuracies and repeatabilities are achieved — even during heavy-duty machining and long periods of operation.

The NHP 5500 has a rotary shuttle-type twin pallet configuration with a pallet change time of 12sec. This, in addition to fast B-axis indexing capabilities, 1.1sec for 90deg, and 1.5sec for 180deg, enables customers to achieve higher productivity.

The integration of a cone air blower that injects high pressure air into the location cones that connect the pallet to the table, removes chips from surfaces resulting in accurate pallet positioning and improved process reliability. The hallmark of all DN Solutions’ HMCs is their rigid design and build — the new NHP 5500 is no exception.

The machine features a heavy-duty three-point support cast-iron bed structure that, in addition to roller-type LM guideways, provides improved stability, which is a necessary prerequisite for improved part accuracies, fast processing speeds and process optimisation.

Although the NHP 5500 is equipped with two 500 x 500mm pallets, the machine’s productivity potential can be increased further through the integration of either a DN Solutions’, designed and built, RPS 5500 round pallet or a LPS 5500 linear pallet automation system.

An investment in these servo-driven and easy-to-install systems significantly increase the productivity of the machine, enabling customers to embrace lights out, unattended operations. As with all DN Solutions’ machining centres (formerly Doosan), the NHP 5500 can be supplied with a choice of control - either the Fanuc 31i/32i Plus with 15in touchscreen iHMI, or the Siemens 840D.

Tony Dale, CEO of Mills CNC, said: “The new NHP 5500 demonstrates the care and attention DN Solutions devotes to improving its already impressive product range. It has many features and attributes that will appeal to precision sub-contractors and manufacturers operating in a variety of sectors including aerospace, automotive, oil and gas and power generation.”