Shanxi Taigang Stainless Steel Co Ltd

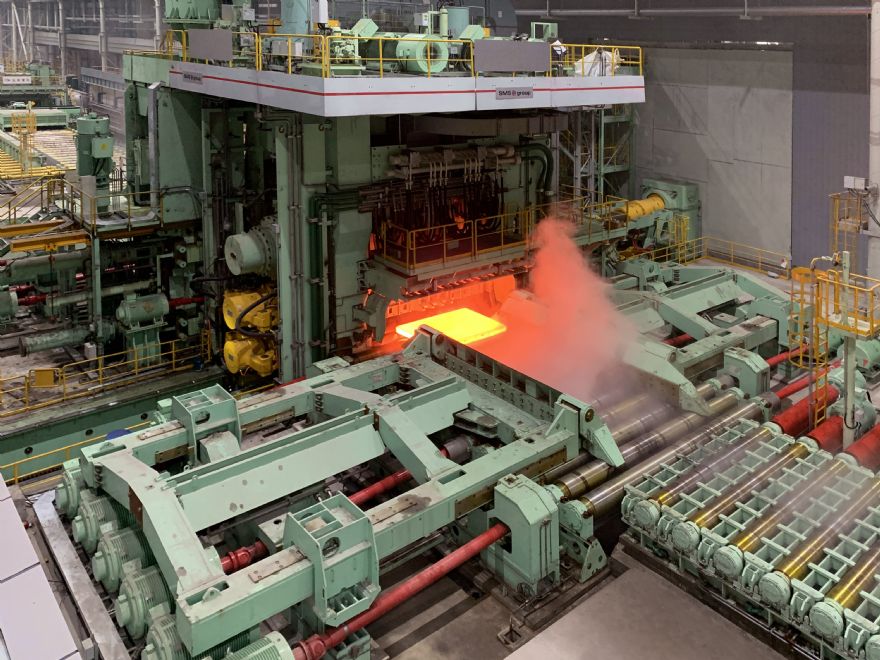

Shanxi Taigang Stainless Steel Co Ltd (Tisco), based in Taiyuan, China, has successfully produced the first plate on its new 4.3m heavy plate mill supplied by

SMS group. It is the most powerful hot rolling mill of its kind ever supplied by SMS having a rolling force of 109MN in relation to the roll barrel length of 4.3m.

The mill is capable of rolling a wide range of materials including carbon steels, quality steels, low-alloyed steels, grades for ship, bridge and pressure vessel construction, weather- and wear-resistant plates, pipe grades according to the API standard, as well as stainless steel and nickel-based materials.

The 4-high rolling stand with attached edger is the central production unit of the heavy plate mill. The vertical edger features combined mechanical/hydraulic roll gap adjustment to achieve extremely tight tolerances. To be able to process even very short slabs, the heavy edging stand is equipped with a newly developed, specially driven support roller table.

The rolling stand is characterised by high rolling forces and a correspondingly high forming capacity. The combination of a very large roll gap opening and the coaxial CVC-plus (Continuously Variable Crown) technology with integrated powerful work roll bending is a new development that allows rolling stock in a variety of materials with thicknesses up to 960mm to be processed.

SMS achieved the extremely high stiffness factor of the mill by means of various technological design features, such as the use of 2.3m back-up rolls. Another feature is the mill’s maintenance-friendly design. Being a market leader in heavy plate rolling technology for many decades, SMS took into account feedback from customers when designing the new mill.

Tisco can now produce plates from a wide range of materials, from cast ingots of extreme dimensions to small slabs sizes, to achieve highly flexible and fast production within the tightest geometrical tolerances.

Designed for an annual production capacity of 700,000 tonnes, the mill can produce plates from 1,550 up to 4,200mm wide within a thickness range from five up to 120mm. The mill’s capability to process advanced grades, such as stainless and duplex steels, nickel-based alloys and super-austenitic grades, into products that meet the needs of markets, such as infrastructure, chemical, shipbuilding and on- and off-shore wind turbine construction for fossil-free energy production, was a key reason why Tisco opted for the SGS group mill.

Han Bingbao, project manager in the plate mill project department at Shanxi Taigang Stainless Steel Co Ltd, said: “Thanks to the outstanding technological expertise of SMS group, we have been able to jointly set a new technological benchmark for this class of plate rolling mills. It was also very impressive to see how smoothly the international teams of SMS Group and Tisco cooperated.”

For the SMS group order handling team, Michael Bohland, project manager, concluded: “We are proud to see how our international team has succeeded in overcoming the mobility and travel restrictions due to the Covid-19 pandemic that made it difficult to visit the construction site. Here, our modern digital conference and communication facilities have proved their value, and they will continue to support us on our way to final acceptance.”