Milton Keynes-based

Axe & Status Machinery Ltd, which offers a range of machinery for both metal cutting and general fabrication, has been appointed as the UK agent for the Italian company Lazzati Spa.

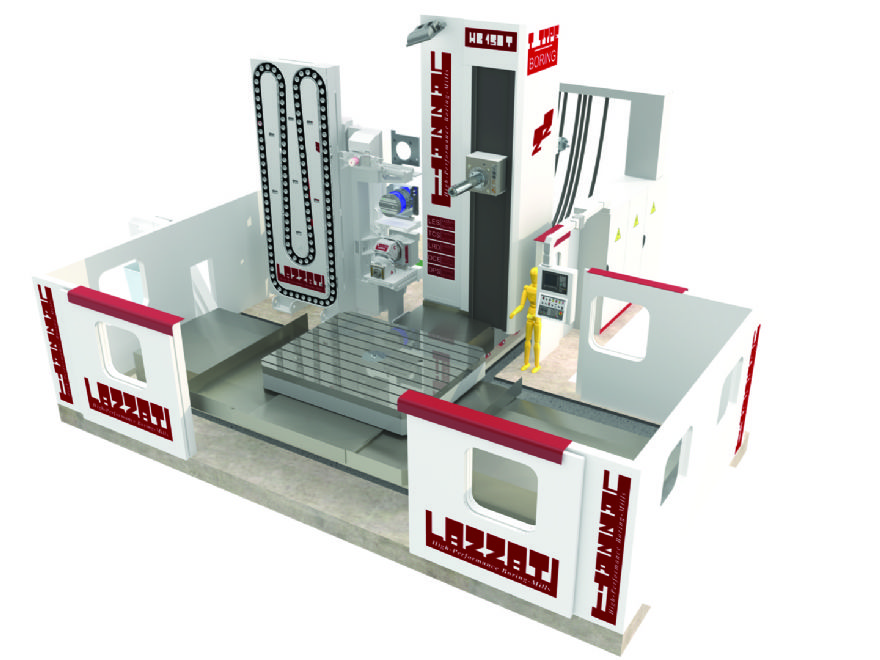

Based in Milan, Lazzati is a leading manufacturer of heavy-duty horizontal boring and milling machines (floor-type moving columns with a table and T-type moving columns with a rotary table) — along with associated accessories. The machines are used for applications in general machining, automotive, aerospace, energy and earthmoving.

Commenting on securing the agency, Steve Thomas — Axe & Status’s managing director — said: “I first saw the Lazzati machines in October 2022 at

Bimu in Milan. It was their quality and build that first attracted our attention, and after discussions on the stand — and following a subsequent visit to the Lazzati factory — we agreed to exclusively represent its range of borers for the UK.

“We had been looking for a boring/milling supplier for some time and Lazzati fitted the bill. The company’s machines are exactly what we were looking for and totally new to the UK; and the more we looked at the range the more we liked it and decided it was perfect for our future policy of also attracting the customers we target — manufacturers of precision heavy engineering products. The size these machines precludes them from being held in stock, and the specification is dependent on individual customer’s requirements. Customer visits to the factory will be part of the buying process.”

They certainly are big machines, for example, the floor-type moving column machines have: vertical head travels (Y axis) from 2,000-7,000mm; cross column travels (X axis) from 4,000-40,000mm; a ram travel (Z axis) of 1,000-1,600mm; and a spindle travel (W axis) of 800-1,100mm. The maximum spindle power range is 75-100kW and the boring spindle diameter ranges from 130-200mm. On the technology front, Lazzati machines feature — among other things — hydrostatic ways, a dynamic compensation system (DCS) that ensures the head is always perpendicular to the column slideways, a thermal control system, and hydrostatic spindle bearings.

Mr Thomas concluded: “We are pleased to be to establishing a partnership with Lazzati and being able to offer such high-quality machines to our UK customers.”