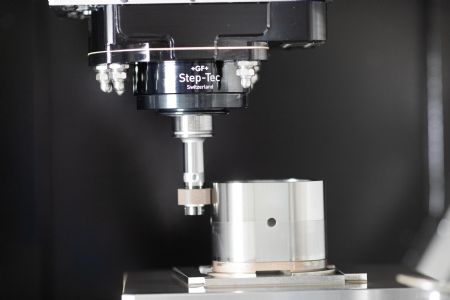

Step-Tec spindles are powerful, fast and flexible. They are ideal for roughing and finishing operations and are used, extensively, by precision part and mould tool manufacturers worldwideStep-Tec AG

Step-Tec spindles are powerful, fast and flexible. They are ideal for roughing and finishing operations and are used, extensively, by precision part and mould tool manufacturers worldwideStep-Tec AG, the Swiss-based motor-spindle design and manufacturing specialist, and part of GF Machining Solutions, has been developing, producing and servicing its range of high-quality spindles for milling, turning and grinding machine tool manufacturers since 1995.

Step-Tec spindles, available within high-performance HVC 120 and 140, and HPC 190, 240 and 290 platforms are powerful, fast and flexible. They are ideal for roughing and finishing operations and are used, extensively, by precision part and mould tool manufacturers worldwide.

Characteristics of Step-Tec spindles include their compact and stable design that deliver proven and reliable performance for machine tool manufacturers and, as a consequence, end users too. Other features include: high-quality bearing systems and preload types that ensure minimal axial displacement resulting in improved accuracies, longer spindle life and higher process reliability; improved thermal stability, via its Opticool and COOL-Core systems, that compensate for temperature fluctuations, and deliver improved part accuracies; and long life, achieved through constant innovation and in-house production of all key elements of every spindle system.

For aerospace component manufacturers productivity, quality and cost down pressures are a constant. The machine tools they use and rely upon must deliver irrespective of the parts being machined and the materials used; for example, from tough Ni/Ti alloys through to lightweight aluminium alloys, as well as exotics and composites.

To meet these challenges there are a range of dedicated and application-specific Step-Tec motor spindles available: high cutting speed and continuous power systems for machining aluminium, high power and low rev/min options for nickel-based alloys and titanium, and twin air sealing systems for composites.

Step-Tec spindles are key components in GF Machining Solutions’ three- and five-axis machining centres and helps explain, in part, why Mikron machines deliver class-leading performance, whatever the application.