Hove-based

CGTech’s Vericut software has created ‘a confidence-boosting, reassuring safety net’ for

Hyde Aero Products Ltd for well over 20 years. As one of the UK’s largest independent engineering companies, Hyde has developed a strong reputation for the design, manufacture and assembly of components for a wide range of customers, services and systems.

From the manufacture of prototype and test components for the medical and tooling industries, through to the fast-response AOG deliveries for aviation and defence clients, Hyde has an established customer base, supported by its highly developed engineering skillset and the verification capabilities of Vericut.

Comprised of over 20 manufacturing units specialising in all elements of metallic component manufacture and processing, Hyde relies on Vericut CNC simulation, verification and optimisation software across a number of its sites. In particular, Stoneswood Precision Components Ltd (SPC), which specialises in the subtractive manufacturing of soft and hard metal aerospace components, has harnessed the functions within Vericut to deliver high quality components, first time.

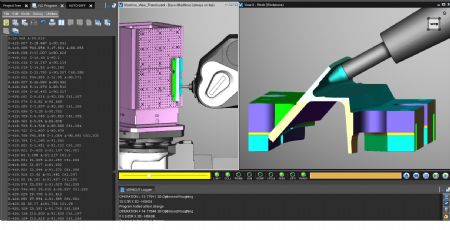

To achieve the ‘right-first-time’ manufacturing ethos at Hyde, Vericut is essential and has cemented its place as the final check before any code leaves the engineering department. Its accurate, high-resolution collision detection, partnered with its detailed level of measuring and analysis, ensures that safe and efficient NC programs are created and issued to the shopfloor.

Machine operators and programmers have confidence and peace-of-mind knowing that NC programs have been independently reviewed by Vericut. ‘First off’ components and ‘prove outs’ pass through various departments within the facility with ease, as dimensional accuracy and overall quality is verified and assured.

Vericut seal of approvalRob Westley, SPC senior technical engineer, said: “From small three-axis aluminium brackets, right through to large, high value five-axis titanium structural components, everything runs through Vericut. No single program, no matter how short, is output to the shopfloor without first being checked and having the final Vericut seal of approval.”

Delivering better products and enhanced components through continuous improvement is top priority for Hyde. Likewise, the engineering teams at sites such as SPC, have also seen Vericut continually improved into an easy-to-use platform that independently and accurately verifies all machining types — from simple face milling to complex five-axis closed wall barrel cutting toolpaths. It is also a great tool for training employees and sharing knowledge.

The live simulation cutstock display in the software provides a way to visualise and demonstrate machining strategies and toolpaths to shopfloor machine operators. In addition, CGTech’s VUE (Vericut User Exchange) meeting and reliable technical support team have been invaluable to the installation of Vericut over the years with the engineering team at SPC.

Tom Whitbread, SPC technical engineer, said: “The simplicity of Vericut and the speed at which it can be used has led to it never being seen as a burden to the programming element of the production chain. Over my five years as a programmer and through my SPC apprenticeship programme, Vericut has always captured my training errors and helped me develop my skills for program optimisation and enhancing the quality of the components I engineer.”

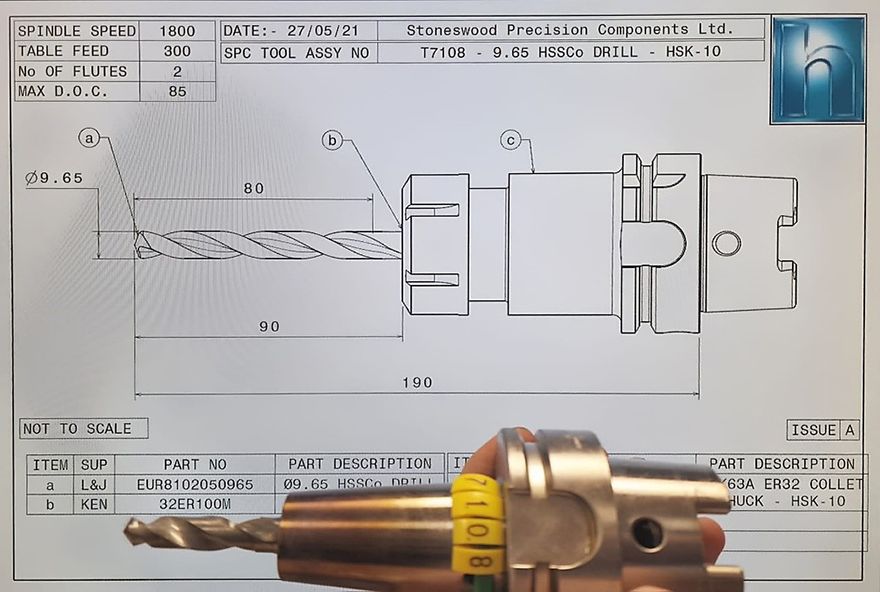

Optimise toolingUsing the Tool Management database, SPC creates accurate detailed assemblies of tools that are perfectly scaled to the cutters. Engineers are then able to optimise tooling, in order to produce a higher quality product in a shorter time frame (through the use of shorter cutters). Likewise, the high resolution and detailed analysis of the proximity between tool holders, stock and fixturing has also led SPC to manufacture complex components through standardised work holding methods. Fixtures can be used on multiple components through the confidence brought about by Vericut, ultimately reducing manufacturing costs.

One of the most powerful modules in Vericut is Auto-Diff, which SPC use on every job. The ability to spot even very minor human errors while programming, or an issue with a particular toolpath or post-processing script, can prove vital. Levels of scrap within SPC have been greatly reduced by Auto-Diff, which highlights gouges or excess material after simulating the machining of a component. By quickly analysing the full component and verifying that it conforms to customer-supplied data, without having to cross reference a drawing or measure individual features, has improved the quality and accuracy of programs produced.

John Kelly, senior manufacturing engineer, said: “The level of confidence brought about by Vericut’s Auto-Diff feature has increased the complexity of the programs that we can produce, allowing us to ‘push the envelope’ to try new strategies and techniques on actual components rather than limiting research and development to off-the-job testing pieces and theoretical scenarios.”

The improved level of confidence brought about by Vericut with features such as Auto-Diff also helps SPC optimise and re-engineer legacy components using the latest technology and strategies available, achieving more efficient and effective methods of manufacture and further improving the high level of component quality.

SPC also uses Vericut to manage production capacity at the facility. The log and run time estimation output by Vericut allows the company to better review and optimise the balancing of workloads and manufacturing capabilities of the various machining cells within the factory. The output estimated run time from Vericut is logged by the engineering department and is used to optimise the ‘lights-out’ production and overnight manufacture of components in the business. In this way, long-running components can be manufactured during ‘lights-out’ production hours, whereas shorter jobs can be run through the day.

Component probingThis understanding of specific component production hours, alongside the implementation of two new Hermle C400 five-axis CNC machines, each with 15 pallets, creates an incredibly efficient method of manufacturing high-quality, tight-tolerance, small-to-medium size aerospace components. The use of component probing, also simulated in Vericut, gives SPC a further boost in confidence, especially through the ‘lights-out’ periods of manufacture.

Chris Lannigan, business development director, said: “This ability to better understand and analyse both the quoting and manufacturing process chain has further strengthened the business’s short lead time machining capabilities.”

To remain competitive and cost effective in this ever-changing manufacturing industry, the quoting and costing of new work and projects by SPC has always been a key to the business. This is strengthened by Vericut’s estimated run time output alongside useful shopfloor feedback helping to fine-tune the company’s quoting capabilities for new projects and customers — allowing for more accurate project pricing and estimated delivery dates.

Overall, Vericut CNC simulation, verification and optimisation software allows Hyde to maintain its reputation as a ‘one stop shop for all manufacturing needs’ for a wide range of different customers and industries. Individual machining sites such as SPC uphold their high standards and customer expectations through the different engineering review and analysis features and capabilities provided by Vericut. It not only gives confidence, but also vital feedback in helping the progression of SPC in the competitive aerospace industry.