Coventry-based

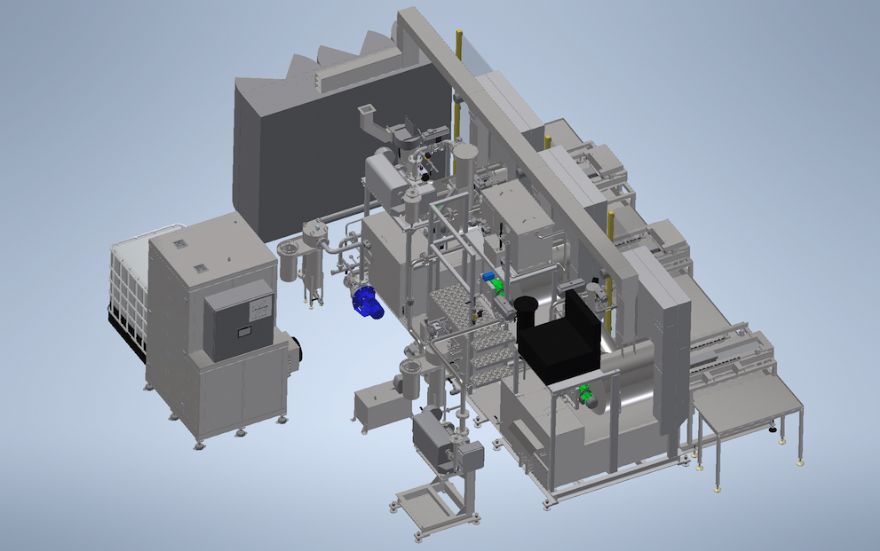

Ultraseal International, a global leader in porosity sealing and vacuum impregnation equipment and technology, will launch its latest development, hot cure water recycling for effluent-free impregnation at

GIFA 2023 (Hall 11, Stand B60), which is taking place in Düsseldorf, Germany from 12-16 June and is the world’s largest foundry trade fair.

The new hot cure water recycling system allows the hot cure waste-water to be treated and reused providing complete effluent free impregnation, in a highly energy-efficient way. Traditionally, impregnation processes generate waste-water from cold wash, rinse, and hot cure tanks. Ultraseal’s first breakthrough was the introduction of rotational cascade washing that enabled blind-tapped holes and machined details to be washed clean of excess sealant without the need for a rinse, thereby eliminating the additional wastewater created.

The company then developed recyclable sealants. This allowed both the washing water and sealant to be recycled from the cold wash solution and re-used. The cold wash tank became closed loop, saving water; while allowing users to recycle and re-use up to 95% of the sealant they purchase.

John Holmes, application sales director at Ultraseal, said: “With this development, Ultraseal has achieved an effluent-free impregnation process, resulting in a high level of component cleanliness, and provides significant commercial and environmental benefits. The technology behind the hot water recycling system is highly innovative. The hot cure solution is pumped into an evaporator to produce steam, this steam is extracted and compressed to economically create super-heated steam.

“The super-heated steam provides a continuous source of energy to maintain the temperature within the evaporator, without the need for a boiler or heat pump (which are inefficient and expensive to run), as the superheated steam transfers its energy through the heat exchange, it cools (95°C), condenses and returns to the hot cure tank as purified water.”

The system offers many cost-saving benefits, including reducing water consumption and effluent disposal costs and eliminating production downtime from the water-change process.