Yanfeng’s installs new safety test equipment at Trenčín Technical Centre in SlovakiaYanfeng

Yanfeng’s installs new safety test equipment at Trenčín Technical Centre in SlovakiaYanfeng, a leading global automotive supplier, has recently expanded its R&D activities in Europe. New equipment has been installed at its Technical Centre in Trenčín, Slovakia, which focuses on the company’s safety systems business. It complements the existing interiors product portfolio and testing capabilities at the site. With this investment in new equipment and technologies, Yanfeng extends its passive safety component development and testing capabilities outside of China.

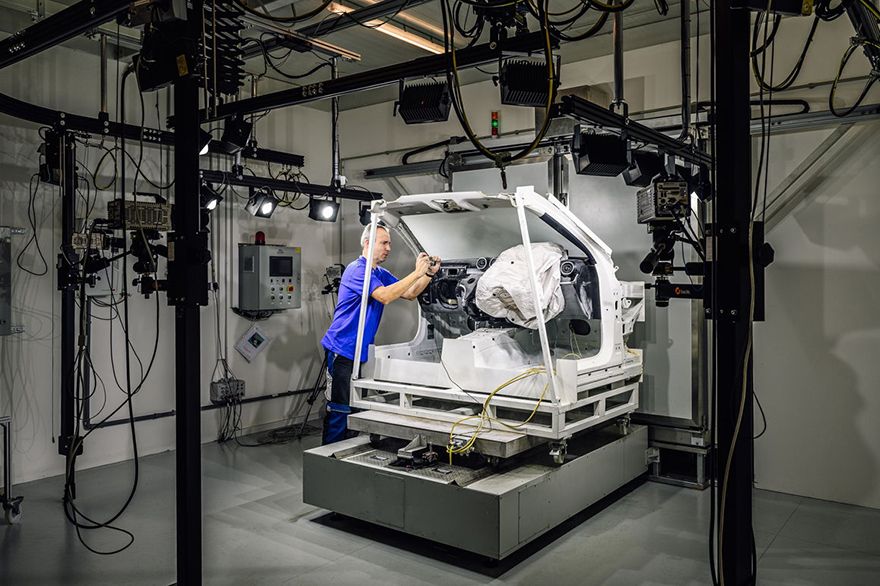

The company has invested around 2.5 million euros in the ‘state of the art’ equipment. These include a mechanical shock test station as well as a drop tester, inflator deployment test machine, an additional climate chamber, a salt spray chamber and also a dust test station, which uses fine dust from the Arizona desert. A new temperature shock tester, an airbag test centre and a robot test system have also been installed.

Ivan Kebísek, Yanfeng engineering director and site leader, explained: “Airbag modules and steering wheels are crucial for driver and passenger safety. This applies both to airbags, which only work once, as well as steering wheels, which must function continuously every day. This means that our products must fulfill the highest quality standards and work perfectly.”

Francois Stouvenot, CEO EMEA and NA at Yanfeng Automotive Interiors, said: “Yanfeng is the only automotive supplier that offers in-house passive safety solutions and interior integration from a single source. With our extensive expertise in interiors, seating, and passive safety, we are able to develop holistic interior solutions with seamlessly integrated safety systems.”

Safety technology The company’s safety technology ranges from a smart steering wheel, that warns drivers through visual signals or vibrations if they unexpectedly stray from their lane, to seating systems with automatic seat belt tightening, restraint systems and airbags. The dust test is performed with a special dust from the Arizona desert and ensures that the functionality of the airbag modules remains intact.

Over the past few years, Yanfeng has been increasing its development and testing capabilities for Central and Eastern Europe (CEE) in Trenčín. Since 2017 the company has invested continuously in additional testing equipment. It is one of two major European R&D sites in Yanfeng’s global engineering network.

The Trenčín site supports the Technical Centre at the company’s European headquarters in Neuss, Germany, with environmental, functional, durability and material tests for automotive interior components and products, including instrument panels, cockpits, door panels and floor consoles. The testing has recently been extended to include the passive safety portfolio.

Mr Stouvenot added: “The Technical Centre in Trenčín is one of 12 locations in our global engineering network, and it has a vital role in our R&D activities. The investment in this new safety test equipment enables us to enhance our capabilities and further support our customers locally.”