The advanced coffee machine — known as ‘coffee machine 2.0’

The advanced coffee machine — known as ‘coffee machine 2.0’Germany-based

norelem, which is supporting a bachelor thesis project at the

Vienna University of Technology, has provided a range of components to enable students to make their idea a reality. With the ambition to visualise as many of the technical processes involved in coffee preparation as possible, students at the university constructed an advanced coffee machine — known as ‘coffee machine 2.0’.

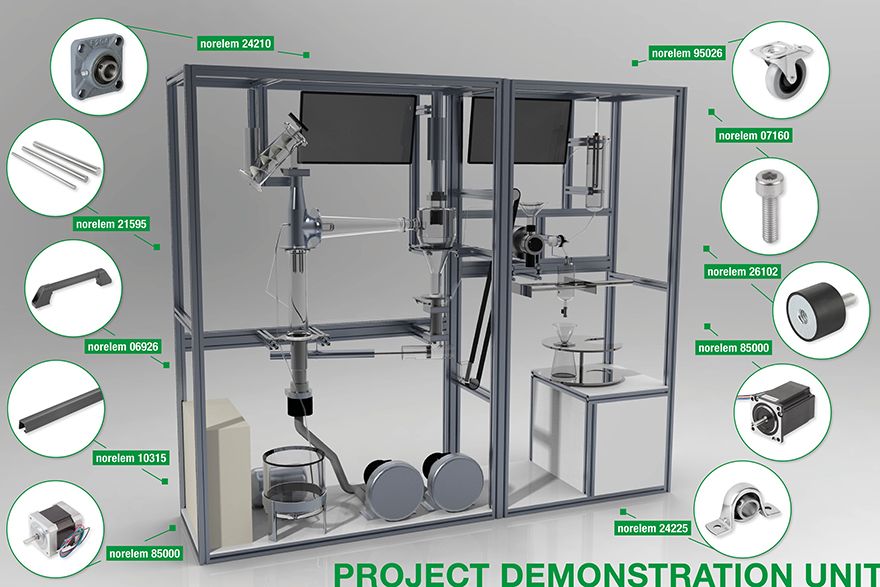

Consisting of two main sections, the machine demonstrates the process of roasting the coffee beans, as well as the extraction process. Within the roasting section, green coffee beans are roasted using a fluidised bed reactor, which uses a cyclone and heat exchanger for separating silver skins. Whereas, the extracting section makes use of a grinder, a heating tank with an immersion heater, a suspension tank, and a filtration device.

The process begins by dosing green coffee beans through a screw conveyor. The beans are then roasted in the fluidised bed reactor with the help of a fan and air heater; as the beans are being roasted, water from a tank is pumped through the reactor’s heat exchanger tube to pre-heat it. The roasted beans are then transported to the mill using a bean lift, where they are then grinded into coffee grounds. The preheated water is further heated in the heating tank and sprayed onto the ground coffee using a spray head. Finally, the suspension is filtered, leaving ready-to-drink coffee.

To make the project possible, norelem provided various components, including swivel castors with a locking system and robust tubular handles which were installed to allow for easy transportation and parking of the machine. Cheese head screws and other standard components were also used to assemble the fluidised bed reactor.

To transport the beans to the mill, a toothed belt shaft and stepper motor were used, and a housing bearing unit was employed to both mount the toothed belt pulley and tension the toothed belt. norelem also supplied maintenance-free housing bearings and a precision shaft, controlled by the stepper motor, to support the load-bearing rotating plate on which the finished coffee was served. Finally, rubber buffers were used to minimise vibrations, while cover profiles were used to protect the system from dirt, dust, and coffee spills.

This project is another in the long list of the student projects that have been supported by norelem. Through the promotion of young talent, the norelem Academy not only realises one of its key business ideologies, but fulfils one of norelem’s wider goals, which is furthering all aspects of the manufacturing industry.

Moreover, the norelem Academy is committed to assisting engineering professionals throughout their careers by offering a variety of training programmes. These include imparting knowledge on commonly used components and providing technical training on various design subjects. The academy places great importance on fostering education and student projects, and therefore offers complimentary materials and valuable technical guidance from its team of experts.