Knowsley-based

Beverston Engineering, an innovative manufacturer of safety-critical components has boosted productivity by 20% after turning its facility into a ‘smart factory’, backed by the expertise and advice of Made Smarter, the North west adoption programme, which helps SME manufacturers invest in new technology and digital skills. The company invested £173,000 in sensor technology and software to connect all 20 machines across its factory to provide real-time visibility of its manufacturing.

As a result, the specialist component manufacturer for the aerospace, oil and gas, and pharmaceutical sectors, has increased productivity by 20%, increased profitability, won new business, and reduced carbon emissions by 10%. Made Smarter, the North West adoption programme has also supported Beverston’s efforts to recruit and train the next generation of digital engineers to accelerate data-led decision-making.

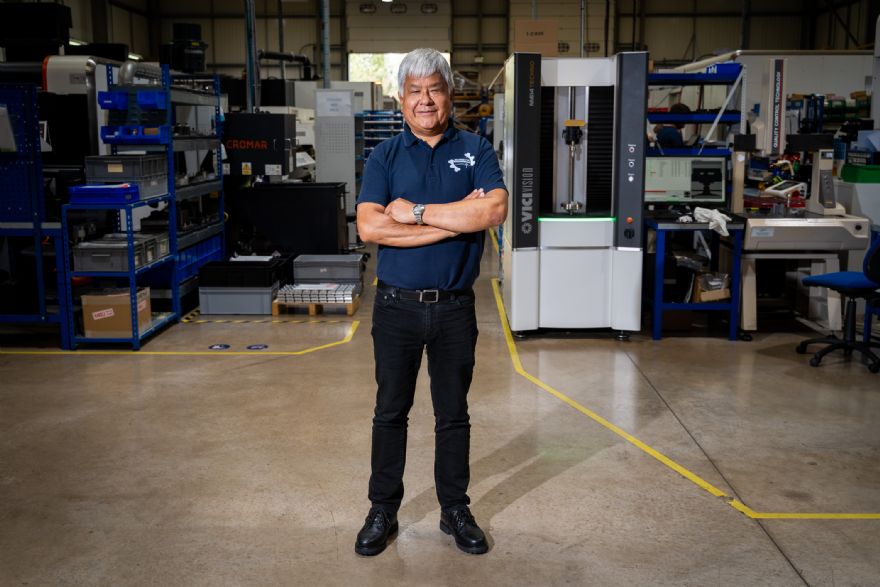

Rod Wah, Beverston Engineering managing director, believes his smart factory proves what can be achieved with targeted support. He said: “Made Smarter has had such a phenomenal impact on the business.”

The company, which will be celebrating its 50th anniversary next year, began working with Made Smarter in 2019 to develop a digital adoption roadmap. A first project in 2020 laid the foundations for the smart factory by enabling connectivity and upgrading IT infrastructure with a dedicated machine data server. The firm also installed sensors to monitor its machines and factory assets.

Beverston Engineering then created a ‘productivity control room’ - a bank of 18 big screens in the centre of the factory displaying real-time factory analytics, such as machine downtime events, availability, and performance metrics to the workforce. A second project in 2022 created a platform which integrated all 20 machines and operators with its ERP and third-party systems, giving Beverston Engineering further real-time insight and analytics, enabling the business to react quickly to challenges and opportunities. The investment came during a tricky time for the business, which had been heavily impacted by the economic shocks of the pandemic, supply chain challenges and energy crisis.

Digital transformationMr Wah explained: “The last three years were incredibly challenging, but we remained committed to our long-term vision for digital transformation. Our customers like Rolls Royce and Collins Aerospace have been blown away by what we have achieved. While our competition went backwards, we have progressed. Our commitment to the vision has helped us win more business and has given us a great opportunity.”

Made Smarter also supported Beverston Engineering to develop new talent. Oliver Miller, an aerospace engineering graduate who began working with the business via Made Smarter’s digital technology internship programme, is now an Industry 4.0 project manager responsible for digital transformation projects. He has also just completed the Made Smarter Leading Digital Transformation programme. Earlier this year, Beverston Engineering was named among 19 recipients of the 'gold' Made Smarter Award for demonstrating excellence in manufacturing.

Donna Edwards, director of Made Smarter’s North West Adoption programme, concluded: “It has been fantastic to have played a part in Beverston's digital transformation. Rod and the team have been enthusiastic programme participants from the beginning. We have supported the company to create a digital roadmap and helped it to invest in the right technologies at the right time. We have also supported the company as it has invested in its people. Our partnership has helped the business weather a turbulent period and come out of it stronger and more resilient.”

The Liverpool City Region has shown a great appetite for digital transformation through Made Smarter. Manufacturers have invested £4.3 million in new technology forecast to create 385 jobs, upskill more than 375 roles and boost the city economy by £52 million.

Launched in 2019, 2,500 manufacturers have engaged with the programme, with hundreds receiving support through grant funding, impartial technology advice, leadership, and skills training to help transform their businesses. The programme has also delivered 334 technology projects in the North West, which are forecast to create 1,550 jobs, upskill 2,772 existing roles, and increase North West GVA by £242 milliom.

To read more about Beverston’s Made Smarter journey, visit the website:

www.madesmarter.uk/resources/case-study-beverston-engineering-revisit here.