Renishaw

Renishaw — a world-leading technology company working in areas that include metrology, motion control, precision machining, healthcare, and metal 3-D printing — says there are many elements to consider when measuring the errors relating to a machine’s volumetric precision, and that to measure them all would take a long time. “For example, there are tracker-type volumetric precision measurement systems where, as the size of the machine increases, the measurement time required increases by square orders of magnitude.”

Japan’s

Volumetric Accuracy Research Institute Co Ltd (VARI) specialises in accuracy measurement analysis and machining accuracy improvement services for production lines; in particular, ‘machine tool accuracy measurement and correction parameter creation services’. Through a research collaboration with DMG Mori Seiki and Kyoto University, VARI supports future development of machine tools, providing an additional service to improve the spatial accuracy of machine tools by using correction parameters calculated using its bespoke algorithm.

VARI says that by improving spatial accuracy, machining accuracy can be improved to reduce rework, adding that the spatial accuracy it aims for is different from conventional geometric accuracy. “Traditionally, motion accuracy such as linear positioning and straightness accuracy has been used for the evaluation of machine tools. There are standards — ISO 230-1 and JIS B 6190-1 — for motion accuracy measurement, and these are used by many machine tool manufacturers for pre-shipment accuracy inspection.

“However, since the motion errors interact with each other, it is not easy to envisage the actual position deviation of the tool tip point from the motion accuracy. This is why VARI developed the idea of spatial accuracy that directly evaluates three-dimensional position deviation for each position of the tool tip point.”

VARI went on to say that with efforts to improve efficiency in machining, reduce scrap, and minimise costs, there is an increasing need to better understand the manufacturing process. “Knowing a machine’s cutting performance before machining is fundamental for manufacturing; and while when evaluating the accuracy of a machine, laser interferometers are becoming widely used due to their high accuracy, the moving axis of a machine can have errors that not only relate to position but also to its vertical alignment and straightness.

“To measure each of these errors in isolation can take a lot of time; and with machines and the parts being machined on them becoming more complicated, it is not enough to simply measure the positional performance. As the spindle moves, errors related to vertical alignment and straightness occur due to friction and other influences on the spindle structure, resulting in a difference between the indicated position of the tool tip and the actual position.”

Machining capability“Subsequently, large errors in feature position, deviations to the contours and surface may occur, and the manufactured parts may not fit to tolerance; and as deviations occur in manufactured parts due to the errors in each machine axis, it is necessary to measure all the errors of each of the machine axes to evaluate the machining capability.”

Renishaw says the position of an object in space is defined by six degrees of freedom, as is the relationship between a cutting tool and a workpiece in a machine tool. As all the errors can be measured directly and at the same time, the manufacturing time can be reduced, and the machine performance accurately evaluated. It is here that the company’s XM-60 multi-axis calibrator introduced a completely new concept for VARI and allowed the measurement of six degrees of freedom in one set-up, regardless of the axial direction.

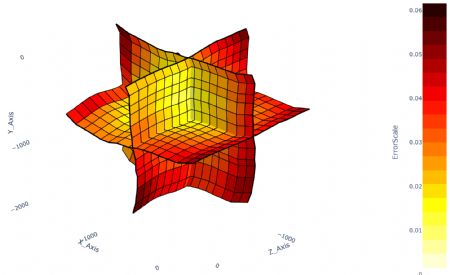

“Machine tool accuracy is usually identified by the measurement of 21 different motion errors, but since these interact with each other, it is not easy to determine the actual deviation of the tool tip from the motion accuracy. A solution can be provided by a spatial accuracy error map, which can be used to visualise the accuracy distribution in the machining space. VARI provides an independent service that measures the spatial accuracy of machine tools, to create an error map that can be used to improve overall accuracy.”

VARI realised that when using the XM-60 multi-axis calibrator, the spatial accuracy measurement time could be significantly reduced, especially for large machines. One customer of VARI’s service said: “You can select past measurement data from a list and easily compare multiple results. To evaluate the machining capability of a machine tool, it is necessary to measure all machine axis errors.

“An object’s position in space is defined by six degrees of freedom, similar to the relationship between a cutting tool and a workpiece in a machine tool. To directly and simultaneously measure all errors, VARI introduced the XM-60 multi-axis calibrator; and as a result, we succeeded in reducing labour costs and accurately evaluating machine performance.”