Software pioneer

CoreTechnologie has upgraded the latest version of its 3-D printing software 4D_Additive with a new lattice structure module. The new functions are used to create individualised structures that enable a customised production of lightweight mechanical components and consumer goods.

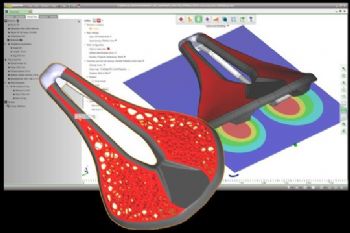

The latest 4D_Additive 1.5 from the Franco-German software manufacturer CoreTechnologie features a completely revised lattice structure module. With the help of the new functions, complex geometries for the additive manufacturing (AM) of lightweight mechanical components and consumer goods, can be quickly created and in a customised way. For example, shoes and bicycle saddles can be customised to meet individual customer requirements.

Thanks to the software’s new lattice structure functions, AM components with additional properties such as progressive damping, highly efficient heat exchange, lightweight design or functions of an assembly integrated into a single component can be quickly developed and optimised. The cell size and grid thickness of the structures can be adapted to the load profile using a colour graphic so that the areas with higher loads are adaptively generated with a denser structure. The software's Nastran interface enables the seamless transfer of data to CAE calculation systems to validate the geometries generated in seconds.

Structural lightweight constructionWith 22 different grid types, internal and external grids are generated on the basis of the original 3-D CAD models. Individual surface areas or parts of the component volume are quickly and easily replaced with lightweight and high-strength structures such as gyroids or Stochastk Voronoi, optimising the CAD model for the respective application.

The simple creation of perforation patterns is possible with the help of new Boolean functions. Thousands of holes of any size are automatically generated so that they are perpendicular to the surface of the CAD model. Interesting applications for the 3-D printing lattice technology include, for example, 3-D printed moulds for vacuum thermoforming or the production of catalytic converters.

CoreTechnologie says that functions for generating parts with lattice structures of different densities, which are manufactured using additive processes, are going to change the way products are developed and improve the performance of many future products.