Leamington Spa-based

Mills CNC Ltd, the exclusive distributor of DN Solutions’ and Zayer machine tools in the UK and Ireland, and a leading supplier of advanced automation system solutions to component manufacturers, is not only celebrating its 50th anniversary this month but also — by the end of this year — expecting to achieve, or even exceed, a sales turnover of £80 million for the first time in its history.

Tony Dale, the company’s CEO, said: “This anniversary is a significant milestone for Mills CNC, and the story of the company over this period is one of growth and success built on innovation, technical excellence, and exemplary customer service.”

Mills CNC was established in 1974 as Mills Marketing Services on an industrial estate in Norwich by entrepreneur Peter Mills, who was a trained toolmaker and had an extensive background in machine tool sales gained, in part, from his time at Beaver Engineering, also based in Norwich. He saw huge potential in importing high-quality CNC machine tools from Japan, South Korea and Taiwan, and selling them to UK and Irish manufacturers. He put this belief to the test in 1974 when he made a deal with the Japanese machine tool manufacturer Howa and ‘took ownership’ of two Howa NC-7 lathes on a ‘sale or return’ basis.

Mr Mills sold both machines within the six months allotted and subsequently set up his new company with a small group of people, a number who had also worked at Beaver Engineering. Mills Marketing Services started as a distributor for many international machine tool companies looking to gain a foothold in the UK. Naturally, the first of these was Howa; others represented by Mills in the early days included Nakamura-Tome and Toshiba.

The aim of the new company was to give UK and Irish customers access to advanced, high-quality, and competitively priced machine tool technologies backed by the type of marketing and after-sales support that would build strong, long-term relationships. A key strength and differentiator for Mills was its applications and projects capabilities, along with a skilled and well-resourced service team.

During the 1970s and early 1980s Mr Mills developed and grew the company, adding South Korea-based Daewoo Machinery (part of Daewoo Heavy Industries & Machinery) to the list of machine tool principals represented by Mills Marketing Services. In 1986 he sold his controlling interest to Haden MacLellan Holdings before retiring and emigrating to South Africa; and with the company under new management, it relocated to new and larger premises in Norwich’s Bowthorpe Road Industrial Estate. That year, Mills achieved sales of 100 machines — considered ‘a real landmark’ at the time.

In 1992 there was a change of name to Mills Manufacturing Technology, to underline the change in focus from being a traditional machine tool distributor to a company providing a wide range of technology solutions.

The period 1996-2014 was a particularly successful period for Mills Manufacturing Technology, being one of significant growth during which there were many notable highlights — including a change in name to Mills CNC Ltd in 2009. These highlights included: the relocation of the company’s entire business operations to Tachbrook Drive in Leamington Spa (started in 2000 and completed in 2001), along with the closure of the two satellite sales offices and demonstration centres in Loughborough and Heathrow; a rationalisation of its distributor network resulting in Mills focusing on Daewoo machine tools (subsequent global mergers and acquisitions saw the Daewoo agency morphed into Doosan-Daewoo and later to Doosan Infracore); the establishment of the CNC Training Academy in 2010; a concerted entry into the vertical machining centre market with a new range of Doosan NM-machines; and the introduction of the MX-range of mill-turn multi-tasking machines into the market.

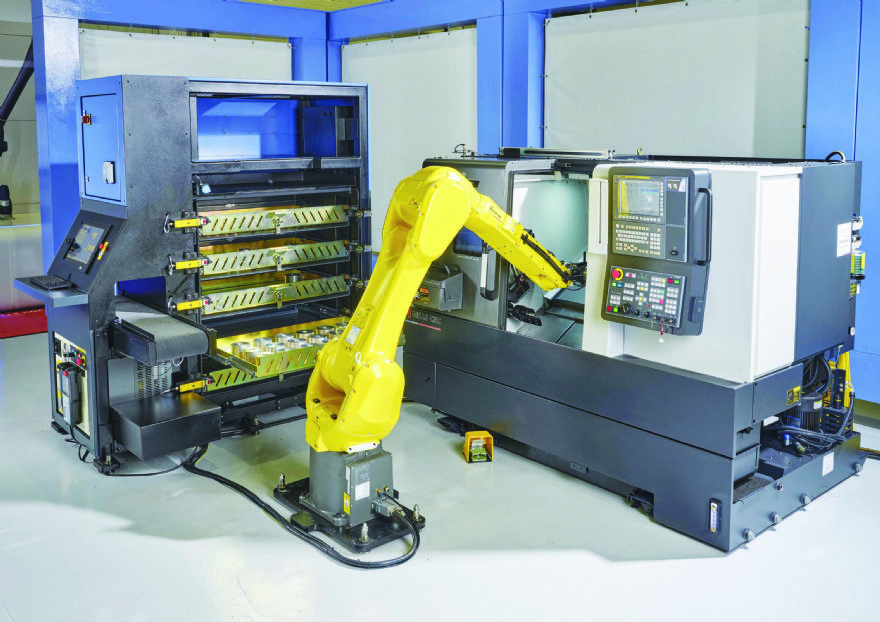

It was from 2009 that Mills CNC began to develop a range of automation solutions in collaboration with Fanuc, installing automated manufacturing cell systems for a number of large OEM customers (the resulting capability subsequently saw Mills CNC create the company’s own ‘Turnkey and Automation Centre’ in 2020/21, along with its Synergi automated manufacturing cells powered by its own proprietary Synergi software).

Regarding financial performance, in 2005 Mills Manufacturing Technology’s turnover was £25 million, increasing to £34.4 million in 2007; and while the 2008/09 global financial crisis affected turnover and profitability, by 2011 the recovery was well underway — a recovery that saw the now-named Mills CNC hit a turnover of £46.9 million. The company continued to achieve significant growth over the following three years, reaching £63 million in 2014. This was also the time when the company increased its presence at the biennial

MACH shows in Birmingham with the booking of the largest stand at the event — something that has continued to the present day.

Economic setbacksDespite a couple of economic setbacks in this period (2014/15 and 2020/21 because of the Covid-19 global pandemic), the decade from 2014 onwards has been one of growth, growth that is attributed to: strong leadership headed up by Kevin Gilbert (2014/15-2021) and Tony Dale (2021-present); a dedicated and loyal workforce; and the introduction of new and innovative machine tool models. These include DVF and VCF five-axis machining centres, multi-tasking SMX mill-turn machines, large-capacity horizontal borers, and double-column milling machines. Mr Dale says these all played their part in Mills CNC’s growth, enabling the company to enter new market sectors and consolidate its position in others.

“The recently signed distributor agreement between Mills and the machine tool manufacturer Zayer in 2022 is further evidence of the company’s commitment to continuous improvement and in providing customers with best-in-class machining solutions. Moreover, from OEMs and Tier One suppliers through to precision sub-contract specialists, the DN Solutions’ (formerly Doosan) machine tools and the Synergi automation systems Mills CNC sells and supports are widely regarded as market leaders.

“The company now employs over 140 people. Over 50% of these work at the Leamington Spa Campus; the remainder, which includes business managers and field-based service and applications engineers, are strategically located around the UK and in Ireland. As for the future, we are going to introduce new DN Solutions’ and Zayer machine tool models; these will include DN Solutions’ DVF 4000 — a new, smaller five-axis machining centre from its DVF range. Furthermore, we anticipate demand for the company’s customised Synergi automated manufacturing cells further increasing, cementing our position as a recognised and valued turnkey-solutions provider.

“The future will also see further development of Mills CNC’s’ Campus facility; especially to our Unit 1, where a major refurbishment programme is expected to be completed very early this year. This will allow the relocation and expansion of the CNC Training Academy. Moreover, at the

MACH show in April, Mills CNC will be showcasing 16 machines in total — including two automated manufacturing cells — on what will be the largest stand at the event.”

Mr Dale also said that this year will also see the roll-out of Mills CNC’s RSTL (regional sales team leader) initiative, to ensure improved planning and coordination of its regional servicing operations, as well as the introduction of ‘robust systems and processes’ that facilitate employees’ skills development and progression. “Over the last 50 years, Mills has demonstrated that providing technically excellent machine tool technologies and innovative automation systems, backed by world-class after-sales services, is a winning combination. The company has everything in place to ensure that its future is as successful as its past.”

Mr Dale added that as part of Mills CNC’s 50th anniversary celebrations a special commemorative brochure has been created. A limited supply of printed brochures will be made available this month and that a digital version can be downloaded from the Mills CNC’ website

here.