As well as the Millturn complete machining centres, WFL provides the necessary software solutions in the form of tailored machining strategies, process design and programming

As well as the Millturn complete machining centres, WFL provides the necessary software solutions in the form of tailored machining strategies, process design and programmingAustria-based

WFL Millturn Technologies (WFL) will unveil its latest high-end machining technologies at

MACH 2024 (Hall 20, Stand 351), which is taking place 15-19 April at the NEC, Birmingham. Visitors will see first-hand the company’s latest applications for different industrial sectors, software solutions specifically geared towards process optimisation, safety and efficiency increases, and learn about the reasons for the establishment of WFL UK Ltd late last year and the resulting transfer of business from Market Harborough-based Kyal Machine Tools Ltd.

WFL offers customers bespoke tailor-made solutions; complete machining is subject to different demands today, and this in the area in which the company excels. WFT is always striving to integrate a wide range of technologies, measuring tasks, finish machining operations, gear teeth and much more into its complete Millturn machining centres, all designed to meet the ever more demanding needs of its customers. Right from the very beginning, its motto has always been ‘clamp once — machine complete’ and that still remains its goal today.

Furthermore, WFL focuses on more than just the machining operation itself — it covers the entire process — defining the machining process, workpiece programming, simulation, production and support throughout the entire service life of a machine.

The company’s objective is to always exceed its customers’ expectations in terms of quality, reliability, and efficiency. Reducing the amount of clampings decreases the risk of clamping errors and consequently improves the process quality. Moreover, embodied automatic measuring solutions ensure the highest possible process quality. These measurement readings can be recorded and monitored in the WFL Process Monitoring advanced software which helps the traceability that is required for components, particularly in aerospace.

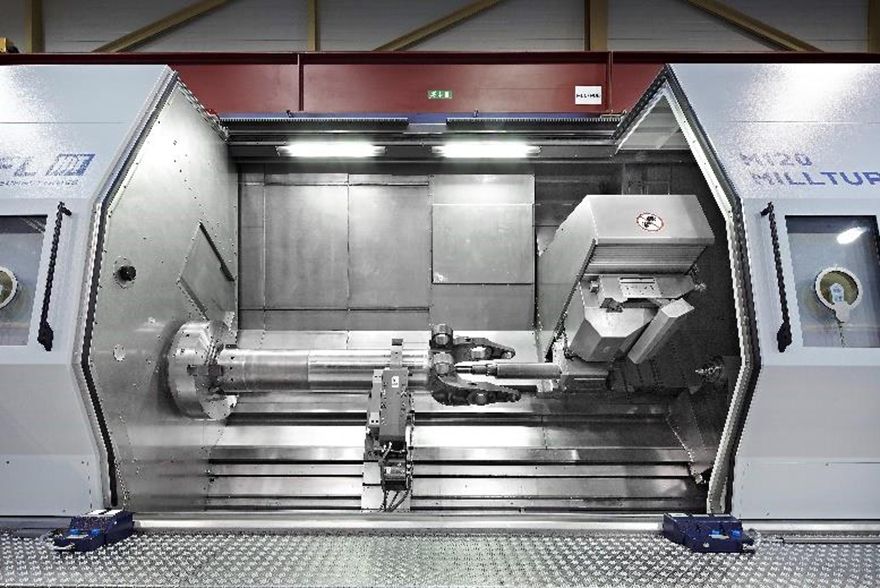

Pictured right: the M20 Millturn is the latest addition to the Millturn range and the ideal solution for users who are looking for a powerful complete machining centre

Pictured right: the M20 Millturn is the latest addition to the Millturn range and the ideal solution for users who are looking for a powerful complete machining centreIn terms of productivity benefits customers enjoy from the implementation of WFL’s machine tools, the main advantage being the reduction in the amount of different machines required to produce a part. This reduction in complexity has many positive effects on the customer’s production environment. For example, less workpiece clampings results in less complexity and simpler production planning. Moreover, a large tool magazine helps in changeover times since all tools can be kept in the machine to accommodate different parts or different clampings. The highest rigidity for efficient machining of exotic alloys and the compact design of the machine, as well as the latest in-machine cutting-edge metrology and process control software round off the total package.

The benefits of automationMeanwhile, automation tasks are also becoming more challenging. Using intelligent software in combination with the relevant automation solutions not only enables workpieces to be loaded and unloaded but also means that machine tools can be set up through automatic replacement of tools and clamping devices. Together with its automation expert,

FRAI Robotic Solutions, WFL supports customers at all stages of a project, from initial concept development to implementation, commissioning, and maintenance of the automated system. FRAI’s gantry robots and robot cells allow for an extensive range of high-quality automation solutions and maximum customer benefit.

Because of innovative developments and intelligent automation concepts, WFL can meet the constantly expanding requirements regarding customised solutions. Its standard components are combined with high-quality purchased components to manufacture flexible solutions for small batches and high-productive series production.

WFL’s latest innovation is the mobileCELL, a generously-sized automated guided vehicle (AGV) with a robot cell design that includes the robot, workpiece, and tool gripper, along with buffer positions for workpieces and tools, as well as the necessary control and safety technology. The machine is freely accessible — it is not blocked or obstructed. The AGV collects the required tools and workpieces in the warehouse, it then travels to the front of the machine, locks itself in place on the floor and exchanges parts and/or tools before moving on to the next machine.

Also on display at

MACH 2024 will be WFL’s realistic 3-D simulation software CrashGuard Studio. This is considered to be an ideal tool for testing and optimising CNC programs after they have been created or modified and this can be done either on an external workstation or directly on the machine control unit. Thanks to the optimisation of the entire processing sequence and an error correction at an early stage, the risks of collisions and of producing scrap parts as well as unproductive run-in and down times are now a thing of the past.

Competitive advantageUsers have a whole range of features at their fingertips and as a result enjoy significant competitive advantage. CrashGuard Studio is an ideal supplement to any CAD/CAM software package and also for the WFL CrashGuard collision prevention software. Data for workpieces, tools and clamping devices can be transferred as required. With the interactive graphics of the Millturn PRO programming software, NC programs can be created efficiently and easily, thereby enabling CrashGuard Studio to become a universal programming system for complex workpieces (without freeform surfaces). Programming can be carried out on an external programming station or directly at the control panel of the machine itself. Furthermore, the programmed machining operations can be checked continually and step-by-step in CrashGuard Studio.

Pictured right: the Settling Rooms in Market Harborough — where WFL UK Ltd is based

Pictured right: the Settling Rooms in Market Harborough — where WFL UK Ltd is basedThe technology cycles of WFL cover an extremely broad range of standard and special technologies for all conceivable cases of application. These program modules, which only require the input of parameters, make it possible to carry out efficient programming directly on the machine control or on a PC. The program can therefore be created for both complex and simple workpieces within the shortest period.

WFL also offers the appropriate technological solution for every gear cutting operation — from filigree internal gears with high accuracy requirements to large external gears, which require high-roughing efficiency.

The UK has always been a very important market for WFL, especially the aerospace industry, and to guarantee the best possible service, continuous and consistent customer support in all market-relevant regions, the company set up WFL Millturn Technologies Ltd UK in November last year.

WFL and Kyal Machine Tools have been working together for over a decade, ensuring that customers in the UK receive the best possible service. The combination of Kyal Machine Tools’ in-house expertise and WFL’s technical expertise delivers the desired production solutions and provides customers with an exceptional level of service and support.

The transfer of business encompasses Kyal employees and in turn maintains all its valuable UK business relationships. This strategic decision aligns with WFL’s global expansion strategy, fortifies its market presence, ultimately benefitting all of its UK customers.