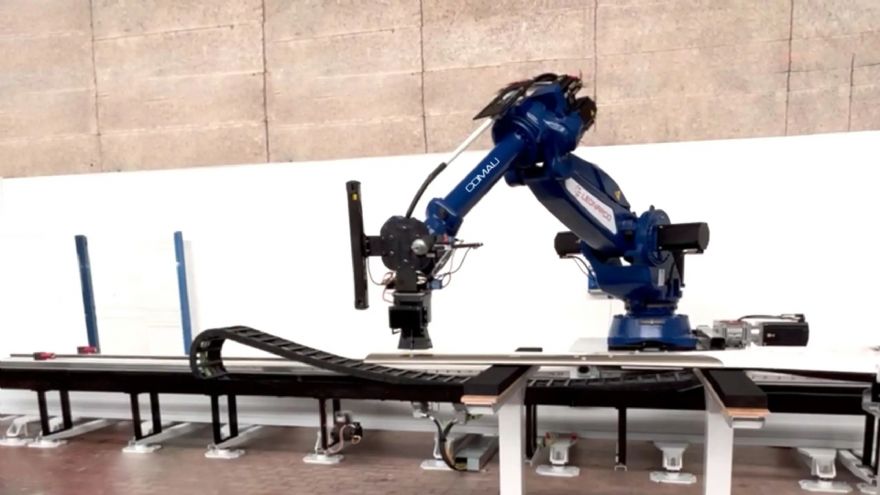

When it comes to testing critical structures such as helicopter blades, the potential benefits of automation increase exponentially, as robotic inspection can combine accuracy with efficiency. To address this need, the Turin-based industrial automation company

Comau and the aerospace company

Leonardo have been working together to develop and test a powerful, self-adaptive robotic solution that can autonomously inspect helicopter blades up to 7m long.

The ‘smart inspection solution’ has been developed as a joint pilot project and tested on-site in Anagni, Italy, over the past year. The system may now move to another site to deliver enhanced capabilities for MRO (maintenance, repair, and overhaul) services.

Using a combination of cognitive robotics, advanced vision systems, and ‘artificial intelligence’, the solution developed by the two companies autonomously performs ‘tapping tests and multispectral surface inspection’ along the non-linear blade, to measure and verify the structural integrity via thousands of readings. Moreover, robotised inspection ‘ensures 100% accuracy within the self-adaptive process’ and allows operators to ‘upskill their positions while enjoying better safety’. The move from manual to robotic automation will also let Leonardo ‘leverage the full benefits of process engineering compared to a manual operation in which experience is often passed between technicians in a non-standard way’.

‘Intelligent algorithms’Each of the companies has shared competencies that optimise the end-to-end inspection process. These include ‘intelligent algorithms’ and advanced path planning that allow the robot to see and respond to its surroundings, as well as a comprehensive data acquisition and processing infrastructure that facilitates ‘optimised sound and image recognition’. As the blades are mechanically stimulated by the ‘smart robot’, the sound response is both recorded and photographed using a multi spectral camera to detect hidden and superficial defects.

Nicole Clement, the head of Comau’s Advanced Automation Solutions Business Unit, said: “Comau’s commitment to the design and development of cutting-edge technologies and solutions for elaborate processes allows us to extend the benefits of advanced automation to mission-critical sectors such as aerospace. The collaboration with Leonardo gives us the opportunity to extend our innovation reach by developing a smarter, data-driven inspection system that provides an objective assessment of key structural elements within a standardised, automated, and highly accurate process.”

Mattia Cavanna, Leonardo Helicopters’ head of technology and innovation, concluded: “This technology demonstration project fits well in Leonardo’s strategy to transform industrial processes through digitalisation. It also aligns perfectly with our steadfast commitment to enhanced technical support, which in turn yields concrete benefits in terms of safety and quality.”