Hardide Coatings

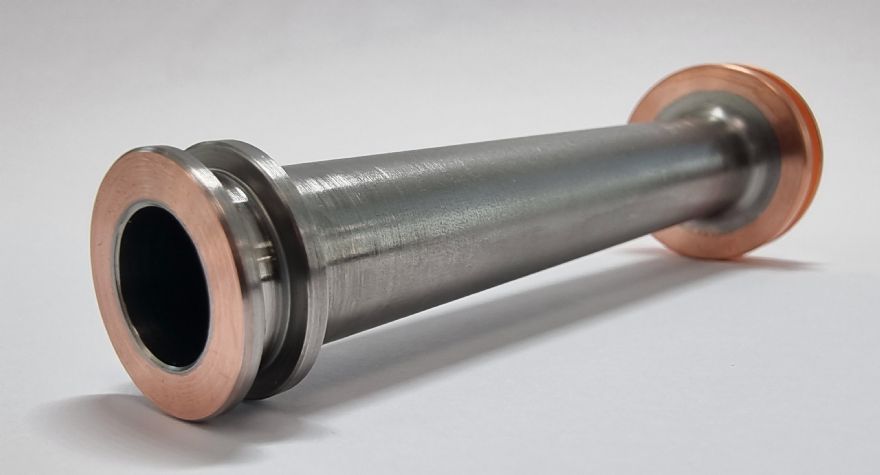

Hardide Coatings, a provider of advanced surface coating technology, has launched the first in a new range of ‘ready coated and enhanced components’ with a JP-5000 4in copper nozzle used in high-velocity oxy-fuel (HVOF) thermal spray coating.

The tungsten/tungsten carbide-based Hardide chemical vapour deposition (CVD) coating has been shown to extend the operational life of HVOF thermal spray copper nozzles by 5-40 times when spraying carbide or metallic-based powders –– and the ready coated nozzles include O-rings capable of withstanding the higher temperatures generated in longer periods of service.

Steve Paul, Hardide Coatings interim CEO, said: “This is an exciting new product development, one that offers significant performance, cost, and environmental advantages to users of HVOF equipment. By Hardide coating the internal diameter of copper nozzles used in thermal spraying, our components offers superior wear resistance and reduced pickup, thereby significantly extending the working life of the part, improving productivity, and reducing spraying costs –– and we recently shipped our first production orders.”

The Hardide coating is compatible with a wide range of coating materials used in HVOF processes, allowing for seamless integration with existing coating systems. The company has been trialling the product with a global OEM in the USA and coating services companies in Germany and Italy. The copper nozzles will be manufactured in Germany and coated at Hardide Coatings’ UK manufacturing facility in Bicester for shipping globally.