Droitwich-based

LMS Precision Engineering has been working with its tooling supplier — Birmingham-based

Guhring Ltd — for over 35 years and was one of the first customers to utilise Guhring’s tool management (TM) vending machines.

Scott Street, a partner at LMS, said: “We are a family-run business that has been operating for over 40 years. We mainly have customers in the aerospace and general sub-contract machining sectors, and have always had a great relationship with Guhring.”

Chris Bush from Guhring said: “LMS uses a broad range of our cutting tools — milling cutters, drills, taps, and thread mills, plus the TM vending machines. In fact, LMS was one of the first customers to use one of these machines, which allowed them to put their resources into providing components rather than manually ordering tools, looking for tools, and managing tool stocks. The TM machine automated all of this — and much more.”

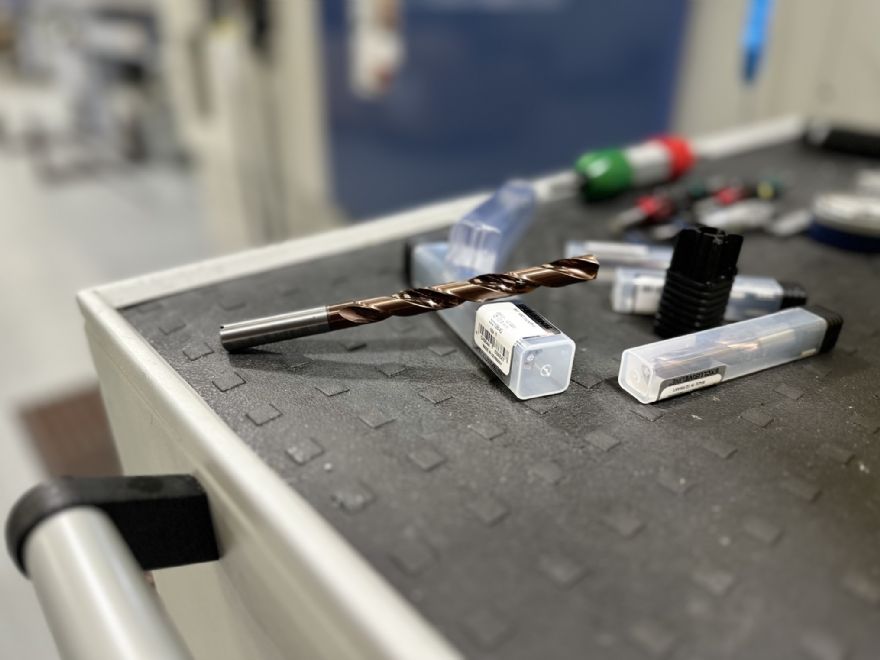

Parts machined on a Matsuura machine at LMS with Guhring milling and drilling products

Parts machined on a Matsuura machine at LMS with Guhring milling and drilling productsRecalling specific product lines that have supported LMS, Mr Street said: “We have had a lot of joy with the Guhring VA Series drill, and now there is the new InoxPro drill, which is bringing us even longer run times. We use Guhring for everything, from end mills such as the high-speed rippers, through-coolant drills, high-speed-steel drills, stub drills — in fact, all our tooling requirements.”

Mr Bush continued: “The benefit of using Guhring as a supplier is that we manufacture our own carbide tools and can make our own grades for specific applications. As a result, we have made tougher grades of carbide that are not as brittle as carbides from other manufacturers, and these are perfect for challenging applications in titanium and stainless steel.”

He concluded: “We have built a brilliant relationship with LMS and we are looking forward to the next 35 years. LMS has got exciting new projects coming through and new machines that they are investing in. There will be plenty of exciting new challenges ahead and we relish the opportunity to help the company deliver results long into the future.”