HORSE

HORSE, a division of HORSE Powertrain Ltd and a leader in innovative and low-emission powertrain systems, has announced that its cutting-edge engine and emissions services at its Curitiba plant in Brazil is now able to support third-party automotive manufacturers. This facility will provide previously exclusive testing services to other South American automotive brands.

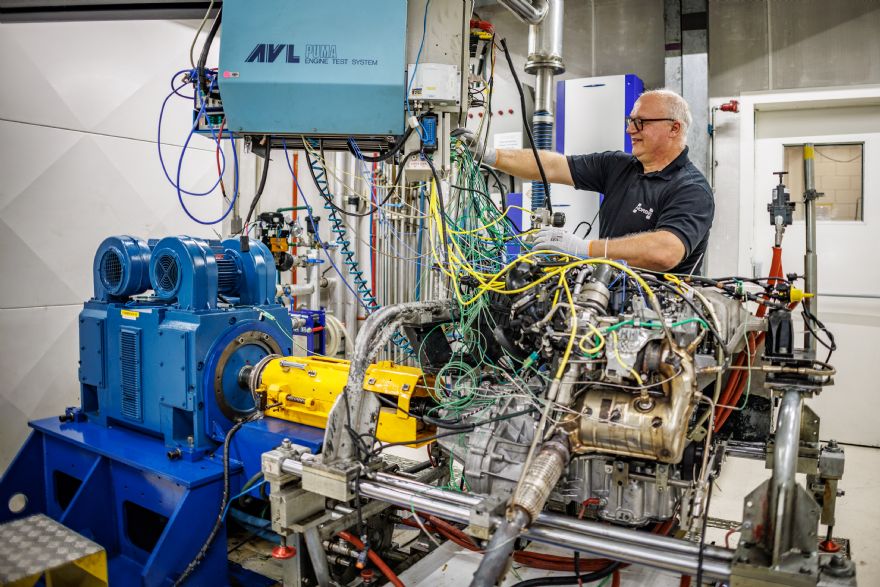

The Curitiba testing facility features ‘state of the art’ equipment, laboratories, and workshops to meet the exacting automotive demands of the region. It provides specialised services including base calibration, durability testing, emissions testing for engines, and management of the Conformity of Production (COP) process.

Wesley Palma, HORSE Curitiba plant director, said: “It is hugely exciting to be opening the doors to our ‘state of the art’ testing facility in Curitiba. Featuring the latest engine dynamometers, emissions laboratories, homologation facilities and a team of dedicated engineers and technicians, this leading site provides a valuable resource for our customers in the region. Curitiba’s capability creates unrivalled opportunities to deliver tailored and efficient solutions for the specific demands of our customers in South American markets.”

The Curitiba test facility features a number of cutting-edge technologies that allow HORSE to develop and homologate powertrains locally for critical South American markets. There are three engine test benches that use the latest equipment from established specialists each used for base engine calibration. Running in two-shift operations, the trio of benches have a combined capacity to run at 6,500hr a year.

Powertrain evaluationDespite HORSE’s Curitiba plant being situated at an altitude of 920m, the engine testing area features an advanced pressurised chamber that allows technicians to simulate conditions at various heights, down to and including sea level. The company also has access to extensive test tracks and driving routes, allowing it to conduct powertrain evaluation under the widest variety of driving conditions and environments.

Alongside this is a chassis dynamometer bench that is used for emission calibration development and final emissions homologation. Running on a four-shift cycle, this system has the capability to carry out testing for 4,500hr a year. The chassis dynamometer facility also features a chemical laboratory that can measure and analyse aldehyde emissions that are a by-product of the ethanol fuel commonly used across the region. Crucially, the facility also meets the exacting ISO 17025 standards for testing and calibration laboratories.

HORSE’s facility also houses a vehicle evaporative test chamber for the complete detection and elimination of fuel vapour from development powertrains. Able to accommodate an entire vehicle, it allows engineers to evaluate the complete fuel system in operation.

Portable emissions measurement systemCO

2 testing can also be carried out, both under laboratory conditions and during on-road driving situations. Using a portable emissions measurement system (PEMS) that is attached to the vehicle and exhaust system, it is possible to accurately capture exhaust emission data in a real-world driving scenario. Combined with the extensive bench testing, it allows engineers to ensure powertrains can be tested and homologated under the latest Real Driving Emissions (RDE) standards.

João Dias, head of the R&D Centre at HORSE Brazil, said: “The Brazilian market has one of most rigorous criteria for testing emissions and fuel consumption in the world, including evaporative tests. We are proud to now offer the market testing solutions that meet these standards, guaranteeing high-quality sustainable mobility.”

HORSE has eight production plants across seven countries, three R&D centres and a head office based in Madrid, Spain. The company produces 3.2 million engine units per year for its customers worldwide.