A team of engineers led by researchers at the

University of Glasgow has developed a system capable of modelling the complex physics of 3-D printed composites capable of detecting strain, load, and damage using nothing more than a measure of electrical current. They say that by being able to predict how new structures can be fine-tuned to produce specific combinations of strength, stiffness, and self-sensing properties, they could help ‘catalyse the development of revolutionary new applications for 3-D printing technology’.

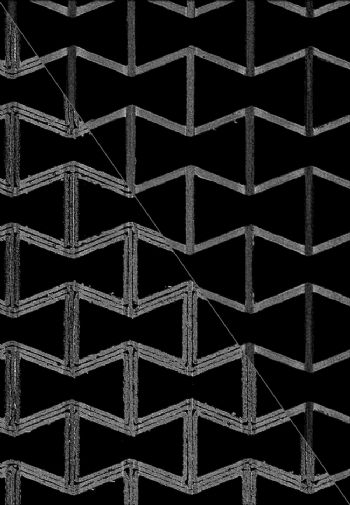

“As this printing technology has developed, researchers have been able to create increasingly complex materials with unique properties. Introducing a lattice of honeycomb-like chambers to a structure’s interior can, for example, allow materials to delicately balance weight with structural strength; and by weaving fine strands of carbon nanotubes throughout materials can allow them to carry an electrical current, imbuing them with the ability to monitor their own structural integrity through a phenomenon called piezoresistivity. When the readout of the current changes, it can indicate that the material has been crushed or stretched, allowing action to be taken to address the fault.”

Professor Shanmugam Kumar, who led the research at the University of Glasgow’s James Watt School of Engineering, added: “Imparting piezoresistive behaviour to 3-D printed cellular materials gives them the ability to monitor their own performance without any additional hardware. That means we can imbue cheap, relatively easy-to-manufacture materials with the ability to detect when they have been harmed and measure just how damaged they are. However, we have not been able to know in advance how effective new attempts at creating novel self-sensing materials will be, but often relied on trial and error to determine the optimal approach for developing these materials, which can be both time-consuming and costly.”

In their paper published as an article in the journal

Advanced Functional Materials, the researchers describe how they developed their system through a rigorous set of lab experiments combined with modelling and used polyetherimide (PEI) mixed with carbon nanotubes to create a series of four different lightweight lattice structure designs that were tested for their stiffness, strength, energy absorption and self-sensing capabilities. Using advanced computer modelling, they developed a system aimed at predicting how the materials would respond to a varied set of loads and validating their predictions via real-world testing.

Professor Kumar concluded: “With this study, we have developed a comprehensive system capable of modelling the performance of self-sensing, 3-D printed materials. Informed by rigorous experimentation and theory, it represents the first system of its kind that enables the modelling of 3-D printed materials across multiple scales and incorporates multiple types of physics.”