Poole-based

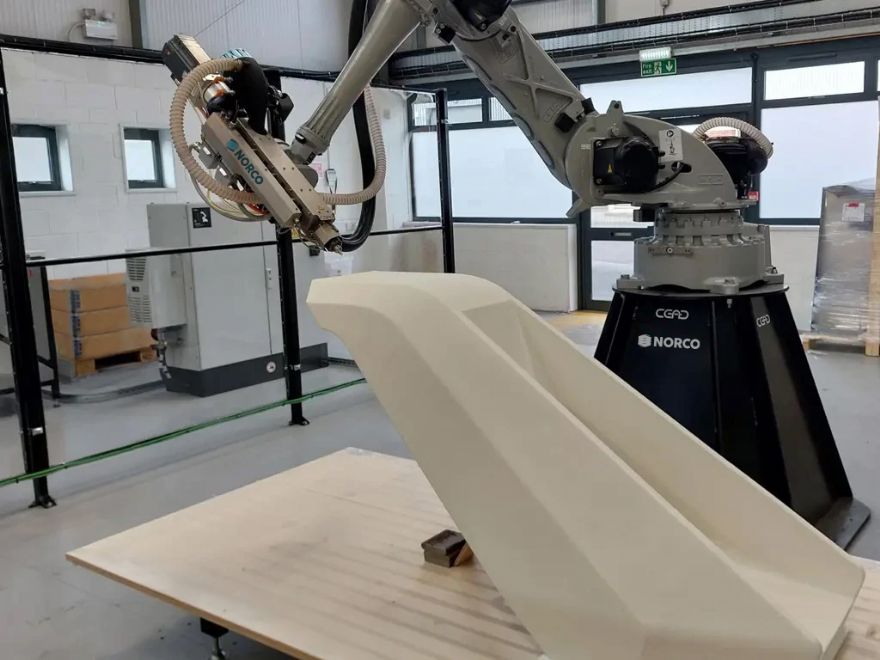

Norco has taken a significant step in advancing its manufacturing capabilities by investing in a six-axis large-format 3-D printer to access new market opportunities and position itself as a leader in delivering innovative manufacturing solutions to a wide range of industrial sectors.

Norco’s capabilites now include:

additive manufacturing — a 3-D printer featuring a robot arm equipped with an advanced S25 extruder, ensuring unparalleled versatility and precision in large-format additive manufacturing (AM);

subtractive five-axis machining — complementing its additive processes, this technology allows the company to refine and finish 3-D printed parts to the highest standards, creating smooth surfaces and integrating fixings or branding as required;

advanced software solutions — utilising leading tools like Ai-Build's AiSync and Adaxis AdaOne to streamline design workflows, optimise production processes, and unlock creative potential.

Norco’s latest investment significantly expands its capabilities in 3-D printing, allowing the company to offer a wide range innovative solutions, including:

rapid prototyping — to quickly iterate and test designs with reduced lead times, moving from concept to production in days or weeks; material versatility — ability to work with a wide range of thermoplastic and bio-based materials, tailored to specific requirements like heat resistance, durability, or unique surface finishes;

customisation and complexity — create intricate geometries and custom parts that traditional methods struggle to achieve, enabling bespoke solutions for specific applications;

sustainability — minimise waste and reduce the environmental impact through circularity-focused practices and the use of recyclable materials in manufacturing processes.

As part of this expansion, 12 new jobs will be created to strengthen the company‘s capabilities in key areas, ensuring that it continues to deliver innovative solutions and maintain the highest standards of precision and durability. Norco’s expertise in both AM and subtractive manufacturing processes allows it to seamlessly transition from design to production, optimising outcomes for its clients and driving innovation around the industry.

Significant milestoneMark Northey, managing director at Norco, said: “This investment marks a significant milestone for Norco as we continue to push the boundaries of what is possible in manufacturing. By expanding our capabilities with the latest technology in AM we are not only enhancing our production processes but also creating new opportunities to serve a wider range of industries with innovative and customised solutions.”

Norco said: “Our dedicated CNC facility, enhanced with the latest equipment for large-format AM is now the hub for our advanced 3-D printing operations. This specialised space enables us to cater to a variety of applications, including:

patterns and moulds — enhancing the efficiency of pattern and mould production by enabling rapid prototyping and reducing lead times and waste;

jigs and fixtures - design and manufacture of bespoke assembly fixtures and trim/drill jigs to provide accurate and repeatable component assembly;

end-use products — producing low to mid-volume series components with exceptional strength and precision for sectors such as marine, aerospace, automotive, wind energy, and defence;

life-size prototypes — bringing creative concepts to life with full-scale prototypes, providing tangible models for detailed testing and product validation; and

architectural design and furniture — facilitating the fabrication of intricate architectural components and custom-designed furniture with sustainable materials, allowing designers to explore innovative and ergonomic solutions.

Norco says the investment in 3-D printing is a key step in its strategy to expand into new markets and redefine what is possible within its manufacturing capabilities. By integrating advanced robotic technology with versatile materials and adding new equipment to its dedicated CNC facility, the company is enhancing its ability to meet the evolving needs of its clients across various industries. Norco’s goal is to help businesses unlock their creative potential, reduce costs, and achieve faster turnround times while maintaining high-quality results.