While

norelem has served the mechanical engineering industry for over 65 years, new markets and opportunities constantly arise. The rapidly growing electric vehicle (EV) sector is a great example of how the company can bring its expertise to help specialist companies create new and better solutions. A case in point is EMBE Machining, a precision machining company based in Markgröningen, Germany. EMBE leveraged norelem’s standardised components to develop an innovative measurement device to test cable insulation in EVs.

Tracing its roots back to the 1950s, EMBE specialises in precision milling, turning and drilling. The engineering firm uses its skill set to develop, design and manufacture prototypes, individual components, series parts and assemblies. It has built a reputation for highly accurate measurement tools, with customers in mechanical and medical engineering, the automotive and motorcycle industries and the electronics sector.

EMBE was tasked with developing a measurement device to test the insulation capabilities of cables in EVs. These current-carrying components must function reliably, even when experiencing extreme heat or cold temperatures. The aim was to provide accurate results that could enable the vehicle manufacturer to make cabling more compact, delivering a market advantage while conserving resources and supporting sustainability goals.

Accurately measureEMBE designed a device to accurately measure the insulation of two wires by applying a test voltage to one wire, which it then moved incrementally closer to another wire until the insulation was breached by an electrical arc. This indicates that the voltage is high enough to break through the wire’s insulating sheath. The resulting current flow between the two wires signals that the insulation has failed and is no longer effective.

Achieving meaningful test results required multiple measurements under varying parameters, such as position, voltage and temperature. In fact, the device’s mechanics had to enable a wide range of motion while ensuring high repeatability at ±0.02mm.

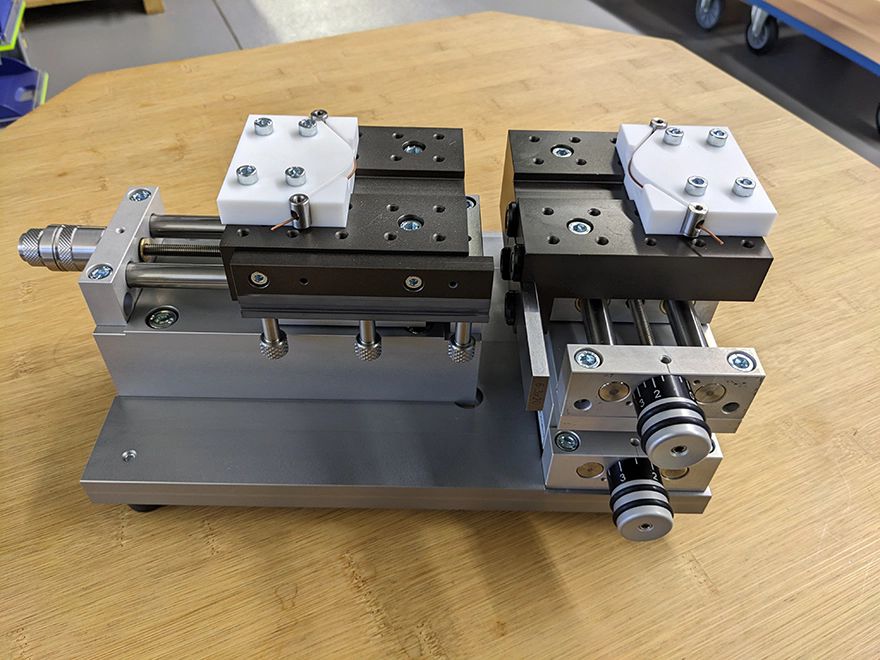

Approximately two-thirds of the innovative device is constructed using standardised components from norelem’s wide portfolio, while the remaining third comprises custom-made parts. Steel parallels from norelem act as reference plates for the dial gauge or for distance measurement, as the component needs to lie perfectly flat in order to deliver precise measurements. A lift table and a positioning table form the base, enabling precise height and Y axis adjustments. These tables are connected into a unit via a mounting base plate, enabling horizontal and vertical movements.

The heart of the device is the second positioning table, which facilitates X-axis positioning. This component ensures the precise approach of the two wires. To achieve consistent results, the adjustment handle was replaced with a ratchet similar to a micrometer screw, allowing samples to be consistently pressed ‘to the block’. This distance serves as a zero reference. From precise positioning tables to reference plates, Norelem’s high-quality parts ensured exceptional accuracy and repeatability, meeting the rigorous demands of insulation testing.

Leveraging norelem’s parts and expertise brought several advantages for EMBE. Michael Pieske, project manager at EMBE Machining, cited three key factors: product quality; quick availability; and an intuitive online shop with comprehensive norelem CAD database.

Quick purchasing decisionsMr Pieske had prior experience working with norelem components at his previous job and brought this knowledge to EMBE. For this project, norelem not only met the technical requirements but also provided detailed product descriptions, specifications, dimensions and other data. In particular, easy access to product tolerance information from the web store enabled EMBE to confidently make quick purchasing decisions.

For EMBE, cost-effectiveness was another important factor — for example, the company realised it would have been impossible for it to manufacture the required spindle-driven guide carriage for under 400 euros. It therefore made more sense to buy it from norelem.

An additional advantage is the free CAD models available for each part, which EMBE uses during the design and finalisation phases of 3-D models. These CAD models can be displayed on a second screen, making it easy to determine availability from stock and look at possible alternatives.

These factors streamlined EMBE’s design and manufacturing processes while maintaining cost-efficiency and reliability. This partnership has not only reduced project lead times but also enhanced cost efficiency, enabling EMBE to quickly deliver cutting-edge solutions to its customers. EMBE now considers norelem one of its core suppliers, using its products in custom fixtures and internal production.