Last month,

Hexagon’s Manufacturing Intelligence (Hexagon MI) division announced it will be collaborating with

JDC-Miller MotorSports. This Minnesota-based racing team — renowned for competing in various IMSA series with vehicles that include those from Porsche, Audi, Oreca, and Duqueine, and more — will be using Hexagon metrology devices to fine-tune the Porsche Hybrid 963 GTP race car ahead of races in the 2025 IMSA racing season.

JDC-Miller MotorSports, which is known for using the ‘state of the art’ in IMSA’s top-tier Prototype class, said: “This collaboration highlights the critical role of metrology technology in maintaining a competitive edge in motorsports, where every detail can determine victory or a loss.”

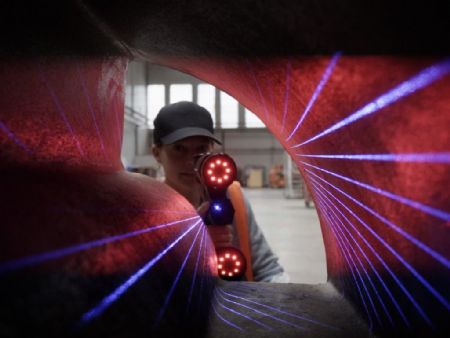

This partnership will see JDC-Miller use Hexagon solutions that include the company’s patented MarvelScan scanning device (pictured below), which will enable the motorsports company to generate highly accurate 3-D scans of vehicles before each race, ensuring they are consistently in compliance with the regulations.

Key featuresHexagon said benefits and key features of the MarvelScan include such as ‘Hole Flash Capture’, edge detection, and photogrammetry, which enable the device to handle complex geometries with high levels of accuracy, resulting in less cleanup required before processing. “MarvelScan also raises the bar for 3-D scanning productivity, as its built-in photogrammetry delivers targetless scanning capabilities that enables full vehicle measurements without the need to place targets or stickers on the vehicle. This saves significant time while at the same time enhancing scanning accuracy — and the system’s high-speed data capture reduces technical inspection time and minimises post-processing for faster compliance and enhanced efficiency.

“Furthermore, MarvelScan has been designed to perform on reflective, glossy, or dark surfaces like car finishes, thereby ensuring reliable performance in challenging inspection environments — and the system is both lightweight and compact to ensure flexibility and ease of use.”

Hexagon added that JDC-Miller’s MarvelScan will be used alongside other metrology technologies, including a Hexagon Absolute Arm, and a ‘Portable Coordinate Measurement Machine’ (PCMM) that offers ‘best-in-class accuracy and compliance with recognised ISO standards’. “All of Hexagon’s devices and technologies are designed to work seamlessly in concert within the same ecosystem, helping to eliminate silos and improve ease of data sharing. This enables JDC-Miller MotorSports to effortlessly expand and adopt additional technology as their challenges and priorities evolve.”

Ensuring complianceJohn Church, managing partner of No.85 JDC-Miller MotorSports Porsche 963, said: “We at JDC-Miller MotorSports are excited about the many ways we can use Hexagon’s technology. In the IMSA WeatherTech Championship series, it is essential for our car to be in compliance at all times. Using the Hexagon tools allows us to arrive at the track and breeze through technical inspection. The Porsche 963 is a precision instrument just like the advanced equipment Hexagon produces, it only makes sense to use the best. We believe Hexagon is a natural partner in the high-tech environment of the GTP class within the IMSA WeatherTech Championship.”

Hexagon said that its collaboration with

Productivity Quality Inc, a leading distributor of metrology systems in the Upper Midwest for over 30 years, means JDC-Miller MotorSports will also receive on-site technical support, enabling pre- and post-race analysis in near real-time. Keith Summers, Productivity Quality Inc’s CEO, said: “This hands-on support will allow drivers, engineers and their extended teams to rapidly review and adjust based on the data, and thereby maximise the car’s performance.

“As the regional partner for Hexagon MI, we will be providing on-site scanning services to JDC-Miller MotorSports using the latest Hexagon metrology technology for data acquisition and analysis. This will include CAD-to-Part comparisons to ensure optimal compliance to design specifications, where a few thousandths of an inch can affect conformance and performance in the very competitive motorsports arena.”

Brian Winters, Hexagon MI’s product manager for articulated arms and hand-held scanners, added: “We are honoured to collaborate with JDC-Miller MotorSports, providing them with metrology solutions that ensure their technologically advanced vehicles meet the rigorous demands that come with competitive racing. Using Hexagon’s metrology solutions alongside on-site scanning services through our partnership with Productivity Quality Inc, JDC-Miller MotorSports can optimise their vehicles, giving their drivers a critical advantage on the racetrack.”

Hexagon MI added that it has a longstanding commitment to advancing motorsports through partnerships with leading automotive racing teams that compete in both

NASCAR and

Formula One.