Venus Aerospace

Venus Aerospace, an aerospace start-up building the world’s most advanced engine system for hypersonic flight, has announced the completion of a

NASA-supported technological advancement — one that will outfit Venus’s record-setting hypersonic engine system during an upcoming flight demonstration later this year.

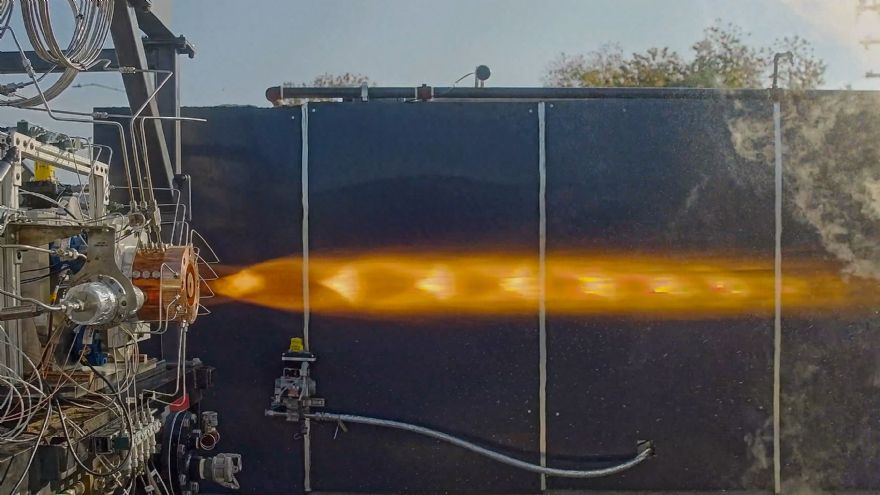

Through a Small Business Innovation Research (SBIR) award, NASA supports high-potential companies building the future of aerospace technology. Venus Aerospace used NASA’s award to test new nozzle designs — the part of the engine that shapes and directs power — for its unique, compact rocket engine. The top-performing design exceeded expectations and will be integrated into a ground-based launch test in the coming months.

Venus Aerospace’s CEO Sassie Duggleby said: “We have already proven our engine outperforms traditional systems on both efficiency and size. The technology we developed with NASA’s support will now be part of our integrated engine platform — bringing us one step closer to proving that efficient, compact, and affordable hypersonic flight can be scaled.”

The engine at the centre of Venus’s flight platform is a Rotating Detonation Rocket Engine (RDRE) — a system long considered promising but never proven at scale. Venus is the first US company to make a scalable, affordable RDRE flight-ready. Unlike conventional rocket engines, the Venus RDRE operates through supersonic shockwaves — called detonations — that generate more power with less fuel.

Readiness for flightAndrew Duggleby, Venus Aerospace CTO, said: “This is just the beginning of what can be achieved with Venus propulsion technology. We have built a compact, high-performance system that unlocks speed, range, and agility across aerospace, defence, and many other applications, and we are confident in its readiness for flight.”

This summer’s flight will mark a significant milestone in demonstrating efficient, affordable, detonation-based propulsion at scale. Combined with Venus’s in-house IP and performance breakthroughs — including previously demonstrated efficiency in the upper 90th percentile compared to standard rocket engines — the integrated system is now one of the most advanced of its kind.

This development builds on a series of advances at Venus Aerospace. Last autumn, the company unveiled a high-speed engine system that enables take-off, acceleration, and hypersonic cruise — all powered by a single engine architecture. While most high-speed systems require multiple engines to operate at different speeds, Venus’s approach eliminates the cost, weight, and complexity of traditional propulsion technology.

The system delivers rocket-like take-off power and jet-like cruise efficiency — all in a remarkably compact form. Its elegant simplicity unlocks major advantages in speed, range, reusability, and cost— enabling a vehicle to accelerate from runway to Mach 5+ without changing engines.

The Venus system supports a wide range of applications, including: spacecraft landers, LEO (low Earth orbit) satellites; space cargo transfer vehicles; rocket kick-stages; and hypersonic drones and missiles.