Photo by

NOAA on

UnsplashMore than 70% of the Earth’s surface is covered by water — yet the marine environment remains one of the least explored and most challenging frontiers for innovation. In recent years, marine engineering has undergone a quiet revolution, fuelled by advanced materials, automation, and precision manufacturing techniques.

These innovations are not only redefining how we explore and utilise our oceans, but they are also transforming how marine-based structures and equipment are designed, built, and maintained.

Traditional marine manufacturing often relied on steel and concrete, but today's materials are smarter, lighter, and longer-lasting. Corrosion-resistant alloys, composite materials, and fibre-reinforced polymers are being used more widely in offshore structures. These materials are not only more resilient to saltwater and pressure but also reduce weight — a key factor in transport and installation.

Additive manufacturing (AM) or 3-D printing, is also becoming a game-changer in the marine engineering sector. Complex components that once required multiple parts and assembly steps can now be 3-D printed in one go, improving precision and reducing potential points of failure. For remote or subsea applications, this offers manufacturers a faster path to prototyping, repair, and bespoke part production. At the forefront of this transformation is

deep.com, an organisation developing cutting-edge subsea habitats and infrastructure. Its work exemplifies how advanced manufacturing techniques, modular design, and next-generation materials are enabling sustainable underwater living and exploration — applications that are setting new standards across the marine engineering landscape.

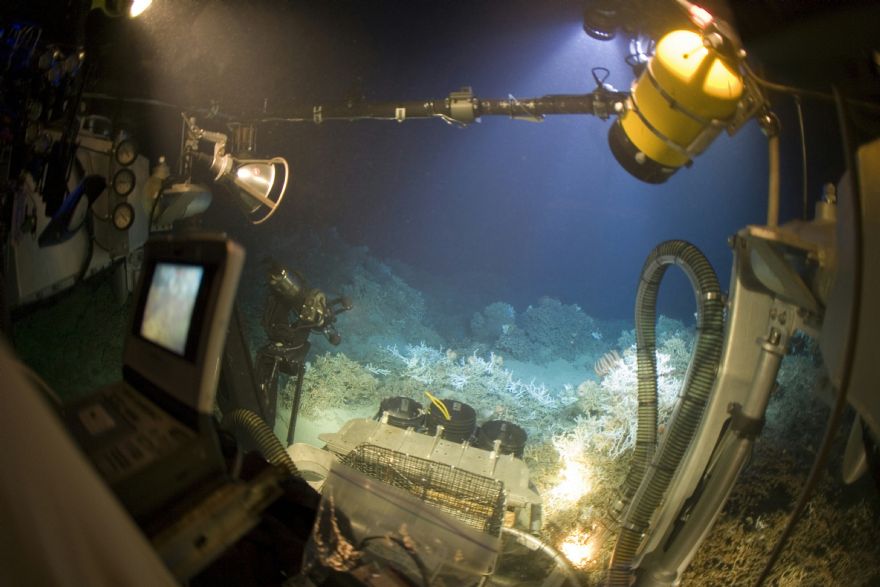

Advanced robotics and remote manufacturing capabilitiesThe harsh conditions of the ocean make on-site manufacturing or maintenance highly risky and expensive. To address this, companies are investing in remote-operated vehicles (ROVs) and autonomous underwater systems capable of performing maintenance, assembly, and inspection tasks.

These systems can be equipped with manipulator arms, cameras, sensors, and cutting tools, all of which are manufactured with extremely high tolerances to withstand subsea conditions. In turn, manufacturers are developing modular systems that can be assembled autonomously or with minimal human intervention. This approach reduces deployment risks and allows for more scalable infrastructure in offshore locations.

With increasing attention on sustainability, marine engineers and manufacturers are collaborating to design systems that minimise environmental impact. This includes quieter propulsion systems for

underwater vehicles, biodegradable lubricants, and recyclable materials for ocean platforms. One area of rapid growth is in the offshore renewable energy sector, where innovations in the manufacturing of floating wind turbines and tidal power systems are creating efficient and durable energy solutions.

The emergence of underwater habitats for research, training, and future commercial use is pushing manufacturing standards even higher. These structures require absolute precision in fabrication to ensure pressure resistance, water tightness, and safety for long-term human occupancy. Manufacturing tolerances are often more exacting than in aerospace or automotive applications due to the unforgiving nature of deep-sea conditions.

Smart monitoring and predictive maintenanceSmart sensors and

data analytics are now embedded into manufactured marine systems, allowing operators to monitor structural integrity, energy use, and environmental conditions in real-time. These data-driven insights enable predictive maintenance, reducing downtime and extending the lifespan of marine assets. Manufacturers are integrating these technologies directly into their products, offering greater value and reliability.

The role of manufacturing in marine engineering is expanding beyond traditional construction into the realm of smart, sustainable, and remote-capable production. With increased demand for deep-sea infrastructure, oceanic research platforms, and renewable energy, the need for precision-engineered, resilient systems will only grow. As marine environments become more central to scientific discovery, energy strategy, and global logistics, the manufacturing industry will play a pivotal role in building the tools and infrastructure needed to support these efforts. Through forward-thinking initiatives, the future of marine engineering is set to dive deeper, push further, and rise to meet the planet’s growing demands.