The fifth axis in a Heller F-series machining centre is designed as a swivelling C-axis head (optionally an A-axis a fork head)Heller

The fifth axis in a Heller F-series machining centre is designed as a swivelling C-axis head (optionally an A-axis a fork head)Heller will present its expertise in the highly productive and flexible manufacture of complex components at the

Paris Air Show taking place 16-22 June (Hall 2B, Stand F194). The focus will be on its F and HF series of five-axis horizontal machining centres (HMCs), which are routinely used in the aerospace industry for producing various sizes of engine component, doors, landing gear and structural parts.

Especially with regard to the machining of difficult-to-machine materials, Heller’s robust, reliable and compact machining centre solutions can be configured with a choice of automation options, all machines being equally well suited to single-part manufacturing or 24/7 high-volume production.

Since the end of 2023, Heller has been rolling out five-axis production centres of various sizes in the new F-series. In addition to having a small footprint, the machines offer high acceleration of up to 7m/s

2 in the linear axes and positional tolerances in X/Y/Z up to 6µm, features that have contributed to an increasing demand for these machines. A further advantage is their large working volume relative to the external dimensions.

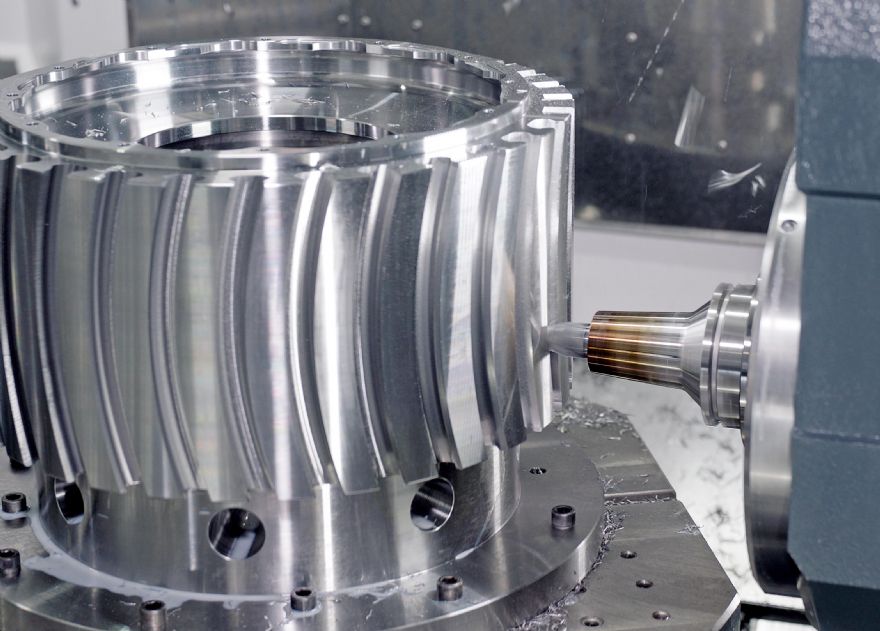

Pictured left: A Heller F 6000 five-axis HMC machining a fan disc

Pictured left: A Heller F 6000 five-axis HMC machining a fan discWith one-hit machining playing an increasingly important role in many aerospace manufacturing applications, Heller has embraced this all-in-one concept and offers an optional turning function for combined turn-milling on the F-series for machines up to 10,000mm in X.

It is implemented by a high-torque rotary table delivering speeds up to 700rev/min, allowing external or internal contouring in the longitudinal or transverse direction in a single setup, as well as the production of undercuts and recesses. Even cutting of external and internal threads is possible. The need for reclamping on separate turning machines is eliminated, resulting in improved component accuracy and reduced cycle times.

Error prevention features include a digital twin integrated into the Siemens Sinumerik One control system, which supports virtual mapping of a production process before the first chips are removed. For manufacturers that do not know the types and quantities of workpieces they will be producing in the future, Heller offers an automation-ready option, ensuring that standard automation options can be added quickly and easily at a later date. The F-series is equipped with an automatic pallet changer as standard. Alternatively, automation systems are available based on robots, as well as linear or rotary storage systems.