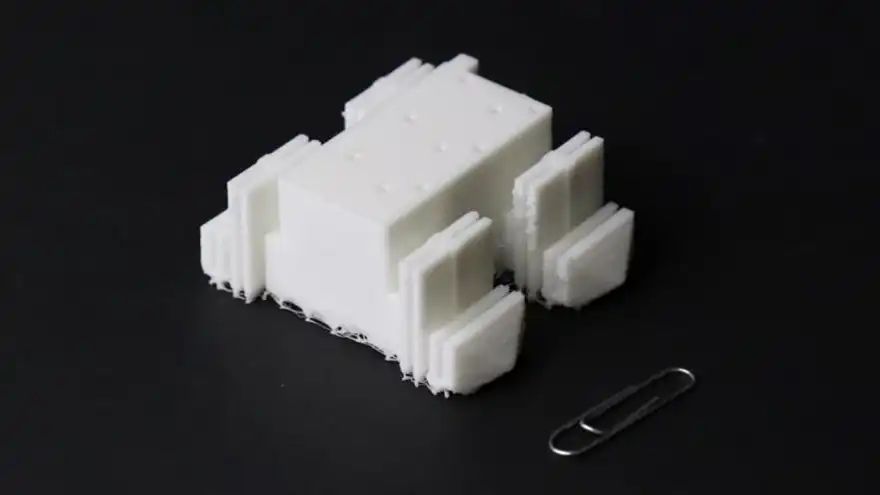

A four-legged robot made of soft plastic next to a paperclip

A four-legged robot made of soft plastic next to a paperclipFlexible, four-legged robots have been developed using a new 3-D printing system, which could pave the way for the use of intelligent soft robotic systems with no electronic parts. Researchers at the

Edinburgh Centre for Robotics say ‘soft machines’ — made from compliant materials such as soft plastics — have huge potential for use in areas such as nuclear decommissioning, the biomedical sector, as well as in space.

Scientists believe a lack of standardised design and manufacturing processes, expense and the need for specialist expertise has so far limited real-world use of the devices. An Edinburgh university team sought to overcome these challenges by developing a low-cost, desktop 3-D printing system for creating soft robots. Their user-friendly setup can be assembled for less than £400 using off-the-shelf parts.

The team demonstrated the capabilities of their new system by creating robots made solely from a soft plastic material and powered by air pressure. Once 3-D printed, the palm-sized devices are connected to a compressed air supply before walking out of the machine on which they were made. The team says building and operating the new system — known as the ‘Flex Printer’ — requires little prior knowledge, with first-time users able to assemble it and begin making robots in just a few days.

Soft robotic technologiesThey have made their designs publicly available to broaden access to soft robotic technologies and to help foster collaboration and improvements to the system. The findings are published in the journal

Device, part of the prestigious Cell Press group of journals. The research was funded by the

Engineering and Physical Sciences Research Council (EPSRC).

The lead engineer on the project was Maks Gepner, with support from Jonah Mack, both PhD students in the Centre for Doctoral Training in Robotics and Autonomous Systems. The lead academic was Professor Adam A. Stokes, head of the Institute for Bioengineering at

The University of Edinburgh.

Maks Gepner, a research postgraduate at the University of Edinburgh’s School of Engineering and Informatics, said: “It used to take years to figure out how to 3-D print using these materials. Using our new platform, anyone can now easily 3-D print things which were previously thought to be impossible. This is a gamechanger for engineers and artists alike. Our hope is that this technology will help drive the next wave of research breakthroughs. Without the long-standing manufacturing and design bottlenecks holding it back, we believe soft robotics is ready to make a major real-world impact.”