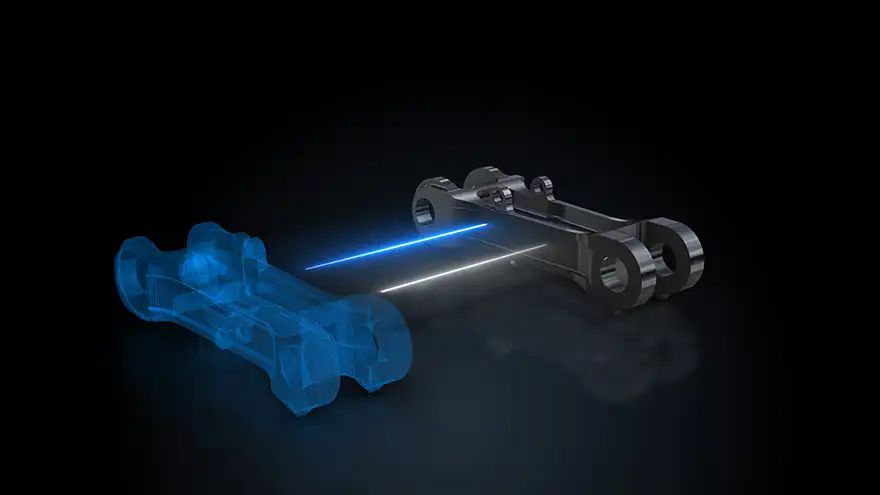

A structural aerospace strut benefitting from technical advances from Walter

A structural aerospace strut benefitting from technical advances from WalterThe aerospace industry stands at the intersection of extreme technological demands and cost-efficiency requirements. With aerospace manufacturers like

Airbus and

Boeing projecting the production of 42,500 new aircraft over the next 20 years, the need for precision machining tools has never been greater.

Aircraft construction is an intricate process that involves a complex array of materials, each presenting unique machining challenges. Aluminium alloys dominate the industry, comprising approximately 60% of aircraft components, while titanium and advanced composites play key roles in structural and performance-critical areas.

Aluminium alloys, particularly from the 2xxx, 6xxx, and 7xxx series, offer an ideal combination of lightweight properties and structural integrity. These materials require sophisticated machining approaches that balance material removal, surface quality, and dimensional precision. High-speed cutting (HSC) technologies have emerged as a vital solution, enabling manufacturers to address the demanding requirements of aerospace component production. It is in this area that

Walter is leading the industry with its cutting tool solutions.

Aircraft construction involves a complex array of materials, each presenting unique machining challenges. As aluminium alloys comprise approximately 60% of aircraft components and require sophisticated machining approaches, Walter’s high-speed cutting (HSC) tools, such as the M2131 and M2331 milling cutters address the specific challenges the industry faces with these materials. The two insert sizes allow for depths of cut of 15 or 20mm, achieving chip removal rates of up to 11 litres per minute.

Both milling cutters work almost seamlessly when repositioned, resulting in smooth surfaces even during pre-finishing. The dense, smooth PVD coating of the cutting edges makes them extremely stable and also ensures that there is hardly any cutting edge build-up. The creative design of the insert seat secures the insert against the high centrifugal forces that occur during high-speed cutting. At the same time, internal cooling channels deliver the coolant directly to the cutting edge to extend tool life and ensure exceptional chip evacuation.

High requirements for the cutting toolsWhile aluminium alloys are used for fuselages and wings, titanium alloys, such as TiAl6V4 or Ti5553, are employed where an exceptionally high degree of rigidity is required, such as in landing gear components, struts, or flap tracks. The hardness and low thermal conductivity of titanium necessitate high requirements for the cutting tools, particularly regarding process reliability. Rapid cutting edge wear and low cutting parameters make machining titanium parts very time-consuming.

Companies that succeed in reducing the machining time per component maintain a clear competitive advantage. Here, the Walter BLAXX M3255 helical milling cutter provides breakthrough solutions. The innovative geometry of both the milling body and the indexable inserts ensures that the maximum number of teeth can engage with the material, while the soft-cutting insert geometry results in positive cutting behaviour that consequently reduces machining times and offers higher metal removal rates.

Heat management poses challenges when machining titanium alloys due to their low thermal conductivity; therefore, an optimised coolant supply to the cutting edge is essential. The Walter BLAXX M3255 is designed to create excellent chip clearance space that guarantees reliable chip removal, even at high cutting rates. The tangential positioning of the two or four cutting-edged indexable inserts allows for maximum cutting power and enables the machining of forged components, where the peripheral zone of the forged skin presents extreme challenges for the tool’s edge.

Ideal for rough machining applications, the Walter BLAXX M3255 helical milling cutter reduces titanium machining time by approximately 22% and extends tool life by around 100% through its innovative insert geometry and optimised chip clearance, which maximises material engagement and removal.

Correlating with the well-filled order books is the requirement placed upon engine manufacturers and the supply chain for machining heat-resistant superalloys (HRSA). Here, too, shorter machining times are highly desirable. The cutting speed of carbide milling cutters on HRSA materials is typically around 50m/min. However, ceramic cutting tools push the boundaries with cutting speeds of up to 1,000m/min, a 20-times improvement.

First choice for milling operationsThe SiAlON ceramics offer excellent possibilities for this, as they are less sensitive to temperature fluctuations than whisker-reinforced ceramics, making them the first choice for milling operations in HRSA. The interrupted cutting during milling causes the temperature at one cutting edge to vary, and the use of coolant can further increase the temperature difference. In the worst-case scenario, the so-called ‘thermal shock effect’ occurs, leading to cracks and even fractures. Dry machining is therefore recommended when machining superalloys with ceramic milling cutters. A positive side effect is that the ecological footprint of the milling operation is improved because lubricants are not required.

Blisks are classic components made of nickel-based alloys. These bladed disks are often rough machined using carbide milling cutters. However, the machining time for this can easily exceed 30min with conventional milling cutters. A ceramic milling cutter with a high feed geometry can machine the same features in just 10min. Feed rates of up to 9,500mm/min can be achieved in a heat-resistant nickel-based alloy with a hardness of 44HRc and a tensile strength of 1,400N/mm

2; such machining values would be expected in aluminium, not HRSA.

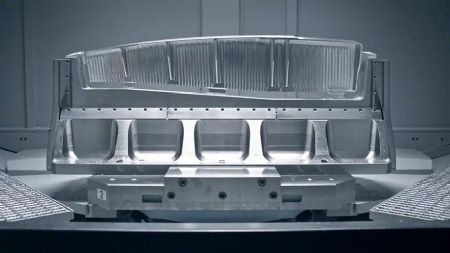

Pictured right: a wing rib for a wide body aircraft machined with tools from Walter

Pictured right: a wing rib for a wide body aircraft machined with tools from WalterFor HRSA machining, Walter introduces revolutionary ceramic milling solutions such as its MC075 high-feed geometry end mills. Available in a range of options including screw-in ConeFit interfaces, the MC075 ceramic end mills can deliver cutting speeds of up to 1,000m/min utilising advanced SiAlON ceramic technology for superior temperature resistance.

Unlike the automotive industry, where mass production dominates, the quantities required in the aerospace industry are comparably small, with the largest manufacturers like Airbus only producing around 750 aircraft a year.

This makes ‘tool-free’ production of components using 3-D printing a feasible alternative, especially as the process enables the production of complex and stable components. Furthermore, it reduces the weight of conventionally manufactured components by up to 55%. This subsequently reduces the consumption of raw materials by up to 90%. From a machining perspective, there are also developments in this area that significantly optimise component production in terms of technology and costs.

Enables more efficient manufacturingFuselage sections, wings, tail units, engine components, and other complex assemblies are now being forged or 3-D printed as close as possible to their ‘Near Net Shape’. It means significantly less material has to be removed. This not only saves material and machining time but also reduces waste — and thus enables more efficient manufacturing.

The question of whether machine tools will still be needed in the future could well be asked in view of developments such as 3-D printing or contour-based manufacturing. The answer is a resounding yes! Almost all 3-D printed workpieces require subsequent machining because their surface quality is usually insufficient for the components to be fitted directly. This is caused in no small part by the so-called ‘staircase effect’ that occurs in the powder bed process typical of 3-D printing. Heat treatment of steel components can also result in hardening distortion, which must be eliminated. Furthermore, support structures must be cleanly removed. All of these factors make cutting tools indispensable — now and in the future.

As an industry leader, Walter has proven the merits of its technical advances in the aerospace sector throughout the manufacturing supply chain. For the production of aluminium structural components, a major aerospace manufacturer implemented Walter’s M2131 milling system for producing aluminium wing ribs. The result was a material removal rate (MMR) increase from 5.8 to 11 litres per min with a 46% decrease in total machining time. Furthermore, the groundbreaking tool geometries of the M2131 system improved tool life by 35%, resulting in a 28% reduction in cost per component.

Similar improvements have been witnessed when machining titanium Ti5553 landing gear components. By adopting the high-feed Walter BLAXX M3255 system, end users have benefitted from cycle time reductions beyond 22% when rough machining. Tool life improvements that are double the performance compared to the previous solution have subsequently yielded an overall 31% reduction in tooling cost per component.

Particularly challenging nicheThe machining of superalloy engine components is a particularly challenging niche where Walter once again excels. When machining blisk components from Inconel 718 (44HRc), the Walter MC075 ceramic milling system has delivered a machining time reduction from 30 to 10min per blade pocket, tripling throughput with existing machine tools and achieving machining cost savings of 65% despite a higher tool investment.

As the aerospace industry commits to CO

2-neutral operations by 2050, Walter’s tooling solutions support this narrative of sustainability and efficiency, contributing significantly with innovations that reduce energy consumption, minimise coolant and lubricant usage, enable more efficient manufacturing processes and support lightweight component design.

Walter demonstrates that advanced tooling is not just about cutting metal — it is about enabling the future of aerospace technology. By combining innovative materials expertise, cutting-edge tool design, and a commitment to efficiency, Walter is helping aircraft manufacturers push the boundaries of what is possible.

The tooling company continues to innovate in response to evolving aerospace requirements with digital integration tools such as its tool management systems that increasingly incorporate digital capabilities. This now reaches far beyond the cutting tool to incorporate comprehensive digital twins of tooling systems for unparalleled tool data management, AI-assisted cutting parameter recommendations, and predictive maintenance tools for monitoring and forecasting tool wear for optimal usage rates.

Walter will be exhibiting at the

Paris Air Show, which takes place 16-22 June. Download a free copy of the complete aerospace whitepaper

A balancing act between high technology and cost efficiency here.