Salzgitter Flachstahl GmbH

Salzgitter Flachstahl GmbH, the largest steel subsidiary of

Salzgitter AG, has placed a major order with

Tenova, a leading developer and provider of sustainable solutions for the green transition of the metals industry, for a walking beam furnace for slabs. The new highly energy-efficient furnace will support Salzgitter’s decarbonisation goals and further consolidate Tenova’s position in the German market, underscoring its commitment to ‘state of the art’ sustainable technologies.

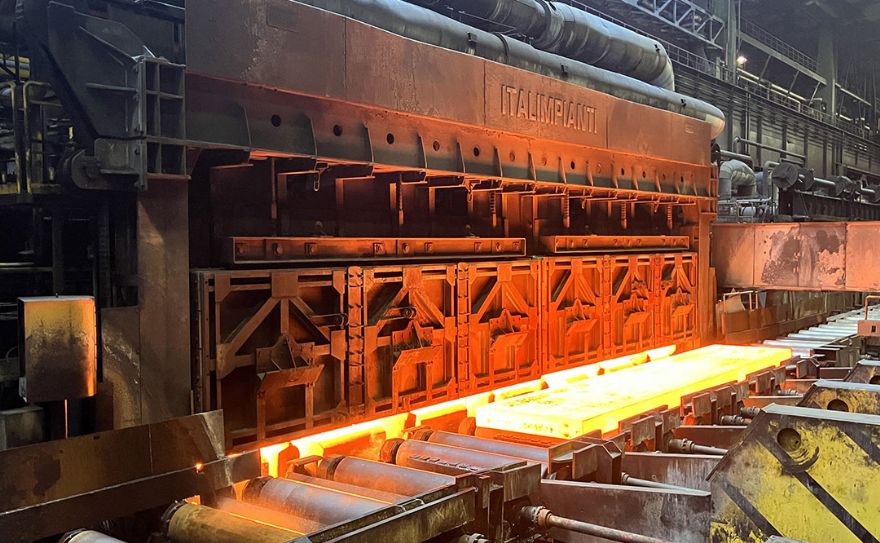

Tenova Italimpianti, the leading technologies and equipment supplier for reheating, heat treatment, strip processing, and acid regeneration plants, will design, supply, and supervise the erection of the entire walking beam furnace. This includes the discharging roller table, charging and discharging machine, and all related electrical, measuring, and control systems, ensuring a fully integrated and automated process.

The furnace has a capacity of 320 tonnes/hr and is designed to process slabs – blocks of cast steel – in single and double-row configurations; it features a combustion air pre-heating system to significantly reduce overall energy consumption. Additionally, it will be equipped with hydrogen burners, enabling the transition towards green energy solutions, and with oxygen injection zones, optimising combustion efficiency and reducing fuel consumption.

Strategic projectThe heat recovery system will capture waste heat to generate steam that will be distributed throughout the plant, thereby reducing the overall plant energy demand. This strategic project marks the third modern walking beam furnace to be installed at the Salzgitter Flachstahl GmbH plant. The two existing furnaces have also been supplied by Tenova Italimpianti.

Thomas Routschek, operations director, hot flat products division at Salzgitter Flachstahl GmbH, said: “The new walking beam furnace is a keystone in our journey towards a more sustainable steel production. Thanks to Tenova’s advanced technology, we will be able to reduce our energy consumption by up to 30% during the process of reheating the slabs. This project represents a decisive step in minimising our CO

2,/sub> footprint and enhancing the overall energy efficiency of our hot strip mill.”

Antonio Catalano, EVP downstream business unit at Tenova, concluded: “We are proud to strengthen our collaboration with one of Germany’s leading steel producers, supporting their goals for energy efficiency and sustainable production. This project reinforces Tenova’s leadership in the field of energy-efficient and low-emission reheating solutions, paving the way for further technological

advancements in the steel industry.”