Advanced Electric Machines Ltd

Advanced Electric Machines Ltd (AEM), based in Washington (Sunderland) that aims to design and build the world’s most sustainable electric vehicle (EV) motors for the global automotive and transport sectors using its rare earth-free technology, warns that as European automotive suppliers scramble to restart struggling production lines following China’s rare-earth export restrictions, the era of rare-earth dependency must end now — before the clean energy transition is crippled.

AEM’s CEO James Widmer said: “Recent plant shutdowns are not an anomaly but a preview of our industry’s future if we continue down this unsustainable path. While our competitors are held hostage by geopolitical tensions and supply chain vulnerabilities, AEM’s rare-earth-free motor production lines can run at full capacity, proving that technological independence is not just possible, but critical to the future of supply chains.

“The crisis unfolding across European manufacturing facilities and others around the world exposes a fundamental flaw in the electric motor industry’s strategy. For too long, manufacturers have accepted rare-earth dependency as inevitable, building entire supply chains around materials that carry the same risks as the oil they are seeking to replace. This approach has created a house of cards that collapses at the first sign of geopolitical tension.”

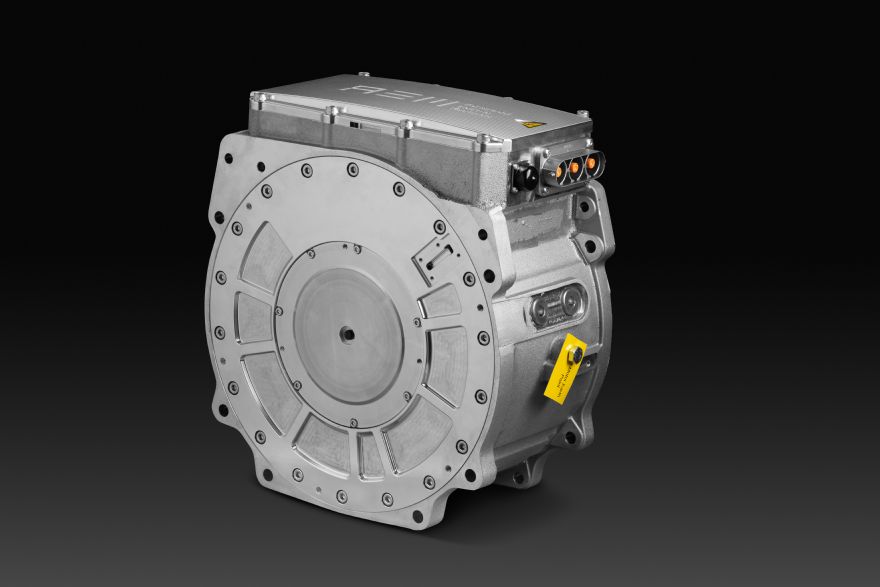

Superior performance characteristicsHe went on to say that the industry’s addiction to rare earths has created a chokepoint that threatens the entire clean energy transition, adding that AEM’s reluctance motor technology eliminates rare earth dependency entirely while delivering superior performance characteristics. “Unlike traditional permanent magnet motors that require neodymium and dysprosium, AEM’s motors achieve industry-leading efficiency using only abundant, domestically available materials.

“Our technology has already been validated across multiple sectors, including passenger car and commercial vehicle applications delivering 95%-plus efficiency, industrial systems operating reliably in harsh environments, and aerospace applications requiring maximum reliability. We are not proposing theoretical solutions, but delivering production-ready, proven technology today. While others are talking about supply chain diversification, we have eliminated the problem entirely.”

AEM was founded in 2017, when it was spun out from Newcastle University’s electric motor research team, led by AEM’s CEO, Dr Widmer, and co-founder Dr Andy Steven. AEM technologies are covered by 46 international patents protecting their motor designs and manufacturing processes around the world.