Surgical parts being manufactured on the Sodick ALC400G Wire EDM at The Engineering Quest

Surgical parts being manufactured on the Sodick ALC400G Wire EDM at The Engineering QuestThe

Engineering Quest, a family-owned precision engineering firm established in the 1970s, has made a substantial investment in advanced manufacturing technology by acquiring a Sodick ALC400G Wire EDM from Warwick-based

Sodi-Tech EDM Ltd equipped with ‘state of the art’ micro wire. This decision signifies more than a simple equipment upgrade; it exemplifies how forward-thinking manufacturers are responding to the evolving demands of high-precision industries, particularly in medical device manufacturing.

The Engineering Quest’s decision to invest in the Sodick ALC400G, supplied by was driven by a surge in demand for its micro-machined medical components. Will Sharpe, operations manager at The Engineering Quest, said: “Over 20 years ago, our customer handcrafted the NHS surgical instruments for eye surgery with a production output of just one or two a day. However, a change in legislation required the instruments to be disposable and not re-used, which immediately ramped up production demand. The customer needed a solution, and we offered a wire EDM solution that could increase production to 250 instruments a week.”

Pictured right: the work envelope of the Sodick machine at The Engineering Quest

Pictured right: the work envelope of the Sodick machine at The Engineering QuestWith several EDM machines at its Milton Keynes facility, Engineering Quest has comfortably met the production demand for over 400 instrument variants, which can be ordered in batches of 10 to 1,000. Mr Sharpe continued: “The instruments are used in eye surgery, so many of these are for the back of the eye. They have got to be very small, very clean and relatively cheap, but we have got to make sure that we can keep up with the demand that has really exploded over the last two years. The parts are now exported worldwide, to customers in Japan, Asia, Africa, and the USA.”

To support this demand, The Engineering Quest thoroughly reviewed the market instead of resting on its laurels with its existing brand and chose the Sodick ALC400G as it represents the pinnacle of wire EDM technology, incorporating advanced features that directly address The Engineering Quest’s manufacturing challenges.

The machine uses rigid linear motor drives across the X, Y, U, and V axes, combined with absolute linear scales to ensure positioning accuracy backed by Sodick’s unprecedented 10-year positioning guarantee. Central to the machine’s capability is its micro-wire functionality, which accommodates wire diameters as fine as 0.03mm. This proved crucial in the purchasing decision, as no other machine in its class could meet the micron tolerance demands of the company.

Mark Palmer from The Engineering Quest provided additional context about the precision requirements: “These are intricate components for microsurgery for the eyes. So you need something really, really small and really intricate to produce these instruments. You have that accuracy with this machine because it has 0.03mm wire, allowing us to undertake micron precision work that customers require.” This ultra-fine wire capability creates incredibly small and detailed features that would be impossible to achieve through conventional machining methods.

Customised solutionRather than purchasing a standard machine, The Engineering Quest collaborated closely with Sodick to develop a customised solution specifically tailored to their medical device manufacturing needs. Mr Sharpe reflected on this collaborative approach: “Sodi-Tech was really, really helpful. Right from the outset, we approached them with the challenges and the drawings already in place. We spent considerable time researching and discussing what we required, the finer details, and they were very receptive to everything we asked.”

Sodi-Tech UK’s Richard Bailey outlined the development journey. He said: “This machine was developed solely for Quest Engineering. They came to us with a problem, and we developed the solution around the 30µm wire capabilities. Some slight modifications were made to the machine to make it perform better, and we also developed a technology base relative to their components.”

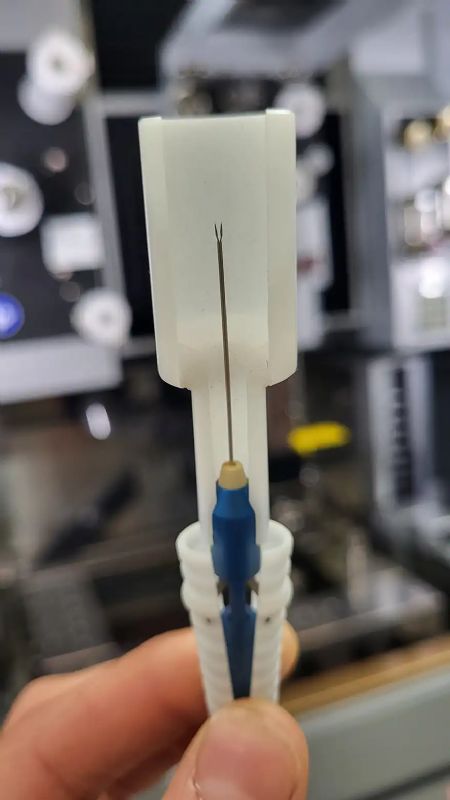

Pictured left: a surgical instrument manufactured on the Sodick machine at The Engineering Quest

Pictured left: a surgical instrument manufactured on the Sodick machine at The Engineering QuestThe machine was configured to utilise water-based dielectric fluid instead of oil, primarily to meet the stringent cleanliness requirements essential for surgical instruments. Richard Bailey explained the rationale: “We developed this around the water machine purely because they need the cleanliness, and also the technology embedded on here has to keep a minimal recast layer. So again, that is a requirement from the customer that we relayed and developed, and now it is embedded into the machine.”

The ALC400G incorporates Sodick’s Smart Pulse Wire control system, which utilises a Windows-based operating system along with a 19in horizontal multi-touch screen interface. The machine features Intelligent Q

3vic EDW technology, an automatic programming system that can import 3-D CAD files and automatically detect machinable profiles, extracting machining contours with minimal operator intervention. The implementation has delivered transformational results for The Engineering Quest. The dramatic production increase to upwards of 500 components per week demonstrates the machine’s capability to scale production while maintaining precision requirements.

Mr Sharpe continued: “Our customers tend to come to us with some very difficult designs, some very difficult things that they need to achieve, but we are here to partner with them and with firms like Sodick, we can deliver at the price points they want by constantly innovating and developing what we are doing. So, all in all, the package they have offered us, from the initial contact to the machine on the ground and the UK support base just up the road from us, has been utterly fantastic.”

The successful implementation and ramp-up in production is an ongoing process. As Mr Sharpe acknowledged: “The machine has been on-site at Quest producing good components for about nine months now and we are continuing to expand our learning curve to maximise the machine’s potential. The next step is to implement automated re-tooling and re-fixturing. Applying our expertise and working closely with Sodi-Tech, we will implement an automated system to achieve around-the-clock automated production in the coming months. Adopting new fixturing and automation techniques, we will set the Sodick ALC400G to run unmanned overnight, further improving our machine utilisation and production output.”