The UK plastics industry, with an annual turnover of £32.8 billion and employing around 160,000 people, remains a vital part of the national economy. Yet moulding firms are under increasing strain, citing rising energy costs are the most pressing issue, with UK processors now paying some of the highest rates in Europe.

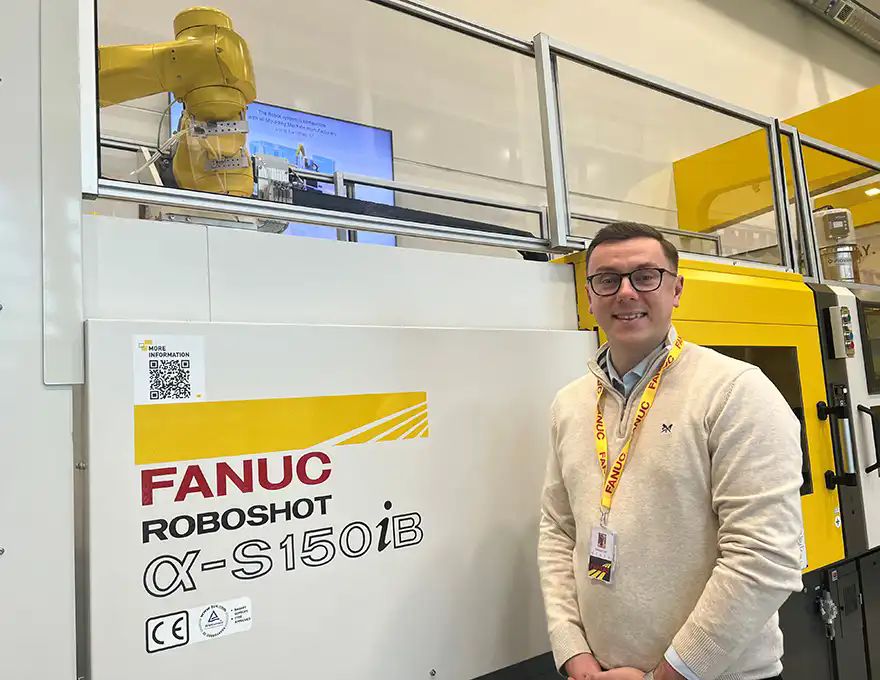

This has severely impacted competitiveness, particularly against European and Far Eastern manufacturers. Energy efficiency is no longer optional — it is essential. Investing in all-electric machines like Fanuc’s Roboshot, available in the UK from Coventry-based

Fanuc UK Ltd can significantly reduce operational costs and improve margins.

Reshoring, once seen as a strategic move to shorten supply chains and boost domestic production, has delivered mixed results. Many firms have found that higher UK labour and energy costs have offset the benefits, leading to disappointing outcomes, thorough research and peer consultation are critical before making such a move.

Engaging Gen ZAttracting new talent is another challenge. The industry suffers from an ageing workforce and a negative public image, particularly among younger generations. Despite the essential role plastics play in healthcare, transport, and everyday life, the sector struggles to engage Gen Z. Promoting the industry’s innovation potential — from robotics and automation to sustainable materials — is key to reversing this trend.

Finally, ageing equipment continues to hold back productivity. Many moulders opt to repair legacy machines rather than invest in new technology, but this is a costly and inefficient strategy. Modern machines offer better energy performance, reliability, and precision. Government support for capital investment would help firms upgrade and compete globally.

For moulders looking to future-proof their operations, Fanuc’s Roboshot offers one of the lowest total cost of ownership packages on the market. Combined with Fanuc’s automation and smart factory solutions, it represents a smart, sustainable investment for firms navigating today’s tough manufacturing landscape.