Horse Powertrain

Horse Powertrain has unveiled the full specifications of its Future Hybrid System at

IAA Summit 2025, marking a significant evolution in hybrid powertrain integration for electric vehicle (EV) platforms. The system, which was first previewed as a concept at

Auto Shanghai earlier this year, is now presented as a production-ready solution designed to enable OEMs to hybridise existing BEV architectures with minimal disruption.

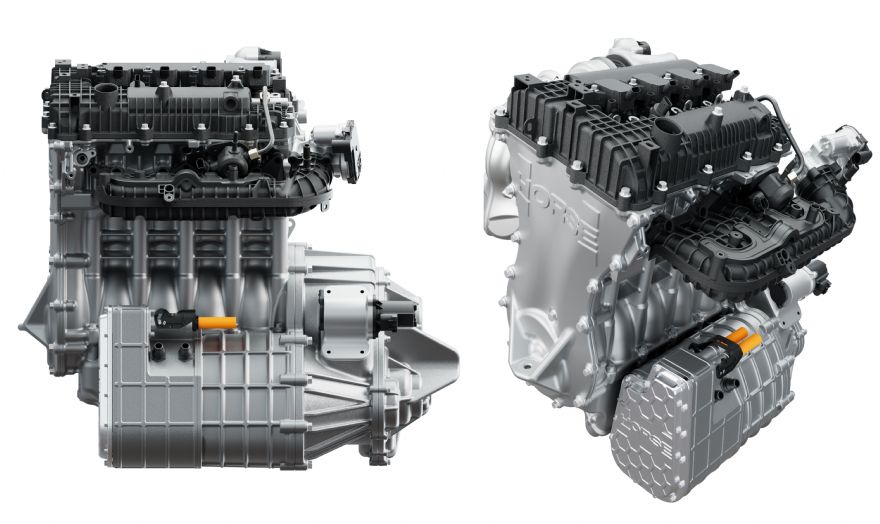

Future Hybrid System is described by the company as an ‘all-in-one’ unit, combining engine, transmission, motor, and power electronics into a single compact package. It replaces the front electric drive unit typically found in BEVs, allowing manufacturers to convert battery electric vehicles into hybrid electric vehicles (HEVs), plug-in hybrids (PHEVs), or range-extended electric vehicles (REEVs) without the need for extensive re-engineering.

Two variants of the engine have been unveiled. The Performance model, measuring 740mm wide, features a dual motor configuration in P1 and P3 positions — one motor at the engine output shaft and another at the transmission output shaft. The Ultra-Compact variant, at 650mm wide, employs a single motor in a P2 configuration, located between the engine and transmission. Both systems use a 1.5-litre, four-cylinder engine and a dedicated hybrid transmission, and are equipped with the full suite of power electronics required for hybrid operation. Integration with DC/DC converters, on-board chargers, and 800V charging boosters is also supported.

Horse Powertrain’s CEO Matias Giannini said: “Future Hybrid System is a perfect representation of what we are about as a company — freeing up the resources of automotive manufacturers and OEMs that would otherwise be spent on reinventing powertrain categories. By providing a frictionless way to broaden their line-ups on existing architectures, we allow OEMs to continue to dedicate all their resources on accelerating EVs while offering a way to maximise the return on their investment in EV vehicle platforms, reducing complexity and focusing on their differentiators in today’s market — design, software, and full electrification.”

Streamlining manufacturingThe system is mounted directly to the vehicle’s subframe, mirroring the installation method of BEV-native electric drive units. This approach not only streamlines manufacturing but also preserves the packaging space in the front compartment, allowing retention of HVAC and PFAS-free air conditioning systems, which typically require more room than legacy systems.

Ingo Scholten, chief technology officer at Horse Powertrain, added: “Compared to traditional solutions, Future Hybrid System achieves an unprecedented degree of compactness; it is shorter and narrower than any equivalent system on the market. Critically, this allows Future Hybrid System to pack a full hybrid powertrain into spaces originally designed for electric drive units, mounted via the vehicle’s subframe. It also unlocks new opportunities for OEMs, such all-wheel drive range-extended EVs in compact vehicles, or the use of PFAS-free air conditioning systems.”

The packaging advantages are particularly evident in AWD REEV applications. Conventional solutions often require stacking an engine and generator atop the front electric drive unit, resulting in a powertrain that is too tall or long for the front compartment. Future Hybrid System, by contrast, enables seamless AWD conversion when paired with a P4 motor at the rear axle, without altering the front-end geometry.

Horse Powertrain is exploring further variants for the future, including three-cylinder configurations that could reduce the system’s width by an additional 70mm. The system supports a wide range of fuels, including gasoline, E85 ethanol flex fuels, M100 methanol, and synthetic fuels, due to its pre-chamber ignition technology, making it suitable for deployment worldwide.