US-based

24M Technologies has unveiled a breakthrough in battery architecture that could significantly reshape the electric vehicle (EV) landscape. The company’s new Electrode-to-Pack (ETOP) system eliminates the traditional cell-to-module-to-pack construction in favour of a streamlined approach that integrates sealed electrodes directly into the battery pack. This innovation allows for a dramatic increase in energy density and design flexibility, while also reducing manufacturing complexity and cost.

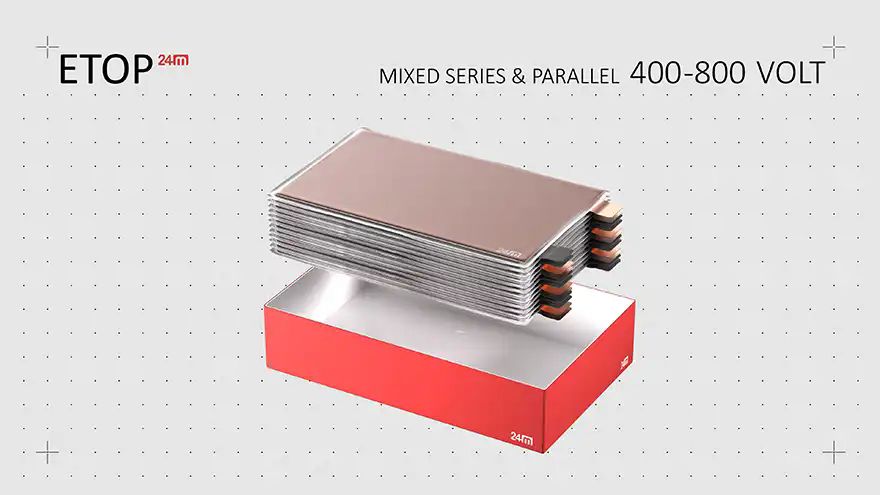

Conventional lithium-ion battery packs are built from individual cells, each encased in materials that do not contribute to energy storage — such as metals and plastics. These inactive components can account for up to 70% of a battery pack’s volume. 24M’s ETOP system replaces this with a sealed cathode/anode pair embedded in thin polymer films, which are then stacked directly into the pack. The result is a battery where up to 80% of the volume is active material, compared to just 30–60% in traditional designs.

This leap in packaging efficiency enables manufacturers to either increase the energy content of a battery pack without changing its size or reduce costs by using less expensive chemistries without sacrificing range. For instance, a 75kWh NMC (Nickel Manganese Cobalt) battery pack — common in mid-sized EVs — could be expanded to over 100kWh using the same chemistry and footprint, delivering a 33% increase in range. Alternatively, the same pack could be built using LFP (Lithium Iron Phosphate), a more affordable and safer chemistry, while maintaining the original range.

Step change in performanceNaoki Ota, president and CEO of 24M Technologies, said: “Minimising packaging materials and wasted space, 24M ETOP brings a step change in performance, replacing traditional cell-to-module-to-pack construction with electrode-to-pack construction, maximising energy density. 24M ETOP makes it easier to build compact, flexible and safe high voltage batteries, presenting a revolutionary opportunity for electric vehicle manufacturers — longer ranges with the same chemistry or the same range with lower cost, safer chemistries, both in the same space. It truly is the closest version of an ideal battery — it is essentially an all-active material in a sophisticated wrapper.”

The ETOP system also introduces new levels of design freedom. Battery packs can be shaped to fit available space within a vehicle, with configurations ranging from ovals to hexagons and beyond. Voltage levels are equally flexible, with the ability to create anything from compact 48V systems to high-voltage 800V packs by connecting sealed electrodes in series or parallel.

Manufacturing benefits are equally compelling. Because each electrode is sealed individually, the system reduces the need for high-precision equipment and tight safety tolerances, improving production yields and lowering capital expenditure. Additionally, ETOP enables cell formation to be carried out in series, further reducing investment in formation equipment — one of the most expensive elements in battery production.

Futhermore, the ETOP platform is also compatible with 24M’s suite of advanced materials, including the Impervio separator, Eternalyte electrolyte, and LiForever electrode. Together, these technologies aim to deliver safer, longer-lasting, and higher-performing batteries by rethinking the internal structure of the cell from the ground up.