As an investor who spends a disproportionate amount of time walking the floors of British factories, all the way from precision aerospace shops in the Midlands to heavy fabricators in the North, I have noticed a recurring theme. We love to talk about the ‘big ticket’ items. We discuss the return on investment (ROI) of that new five-axis DMG Mori, we debate the merits of collaborative robotics and we wring our hands over the volatility of the wholesale energy market.

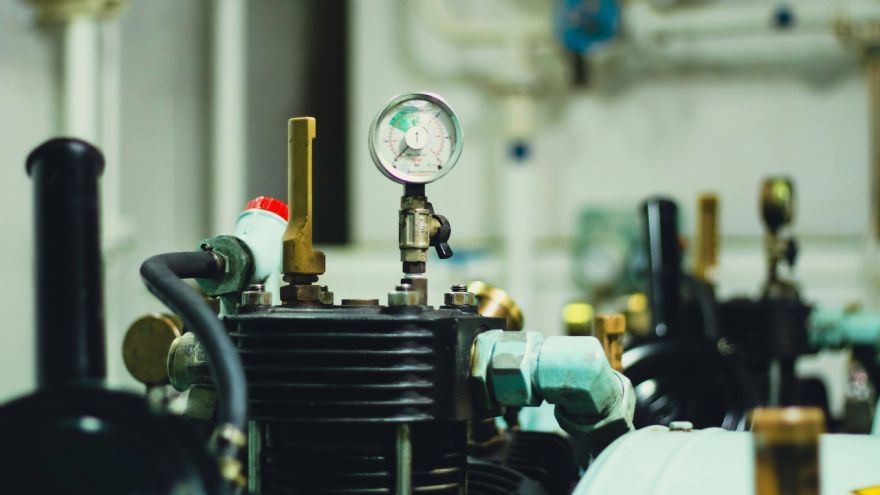

But while we are busy admiring the shiny new CNC mills, there is usually a machine sitting in a dark corner of the facility, often covered in a layer of grime, that is quietly eating the profit margin. I am talking, of course, about the air compressor. In the UK manufacturing sector, compressed air is often referred to as the "fourth utility." It is essential, it is expensive and historically, it is woefully managed. With industrial electricity prices remaining a dominant concern. Truth is, we need to stop looking for complex financial hedges and start looking at basic mechanical efficiency.

The physics of wasted cashThe problem is not necessarily the compressor itself; it is how we treat it. A compressor is essentially a giant lung. It inhales massive volumes of ambient factory air (laden with oil mist, metal dust and general grime), compresses it and sends it down the line.

The efficiency of this entire process relies on the intake. When an air intake filter gets clogged, the physics change. The compressor has to work significantly harder to pull the same volume of air through that restricted medium. This creates a ‘pressure drop’. Here is the part that should concern any CFO — for every 1 bar of pressure drop at the intake, your energy consumption spikes. You are not producing more air; you are simply paying more to produce the same amount. You are effectively paying a ‘dirt tax’ to the utility company.

This is where the distinction between ‘a filter’ and ‘the right filter’ becomes a line item on the P&L. Many shop managers treat filtration as a commodity, buying the cheapest white box that fits the housing. This is false economy. Optimising the air intake with robust, heavy-duty

machinery filters is one of the lowest cost interventions available to reduce parasitic energy load in the plant. A premium filter with lower initial flow resistance and higher dust-holding capacity keeps that differential pressure low for longer. It allows the machine to breathe freely, keeping the amp draw down and the energy bill manageable.

The ‘fit and forget’ fallacyI once visited a die-casting facility that was running three shifts a day. Their compressors were the lifeline of the plant. When I asked about their service intervals, the maintenance lead shrugged and said they changed the filters ‘when the service light comes on’.

That service light is a lagging warning. By the time it illuminates, you have likely been running at suboptimal efficiency for weeks.

In 2026, the ‘smart money’ approach to maintenance is shifting from "reactive" to "efficiency-based," a strategic pivot consistent with the investment priorities highlighted in the

Executive Survey 2025. We are seeing savvy factory owners moving to high-performance filtration media (often using nanofibre technology) that can handle the aggressive contaminants of a metalworking shop without restricting the airflow.

This logic applies beyond the compressor room. Consider the mobile plant. You know, the forklifts, loaders and telehandlers that move raw materials. In the current supply chain climate, replacing a blown diesel engine in a 4-tonne forklift is a logistical nightmare. Ensuring that your material handling fleet is equipped with OEM-grade machinery filters prevents the logistical bottlenecks that starve production lines. If the forklift fails due to dust ingestion, the £500,000 mill it feeds stops running. The filter cost is negligible; the downtime cost is catastrophic.

The hydraulic hygiene factorThere is another invisible vampire to consider: Hydraulic oil. As UK manufacturers "re-shore" more complex work, the tolerances on our machines are getting tighter. Modern hydraulic presses and injection moulding machines use servo-valves with clearances measured in microns.

If you are running cheap filtration on your hydraulic power packs, you are inviting "silt" into the system. This does not always cause a catastrophic failure. Instead, it leads to 'stiction' – valves becoming slightly sticky, cycle times slowing by half a second and reject rates creeping up by 1% ± over the course of a year, that 1% is a fortune.

The verdictWe often overcomplicate efficiency. We look for AI solutions and digital twins, which are fantastic, but we forget the basics.

If you want to improve your factory's resilience against high energy prices, start with the low-hanging fruit. Go check the compressor room. Check the hydraulic packs. If you are restricting your machines with substandard filtration, you are burning cash. In this economic climate, that is one manufacturing defect we cannot afford to make.