DLC coating process

Posted on 13 Jun 2008. Edited by: MM. Read 1174 times.

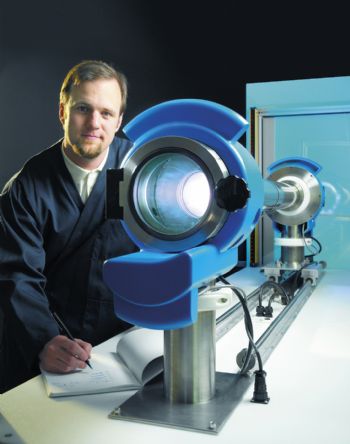

Tecvac Ltd, of Swavesey near Cambridge, now offers a DLC (diamond-like carbon) coating process for internal bores, pipes, cylinders, tubes and pump parts. Developed by Sub-One technology, the Inner Armor plasma coating process provides a very hard and corrosion-resistant film up to 50µm thick that is inert, bio-compatible and environment-friendly, and can reduce friction losses to very low levels.

Tecvac has identified applications in aerospace, fluid engineering, medical devices and powder processing. It expects to find many other internal applications where DLC coating has previously proved difficult or impossible to apply.

Inner Armor DLC coatings can be conducting or insulating, and they can withstand high loads at operating temperatures of 450°C. Application temperatures for a variety of formulations are below 200°C, which enables hollow engine parts to be coated with DLC. This means that costly high-performance alloys can be replaced by lower-specification steels.