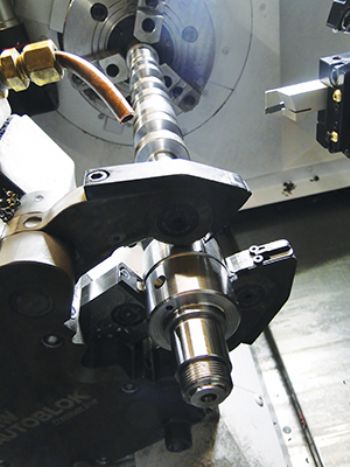

A new DMG Mori NLX 2500 machine (

www.uk.dmgmori.com) delivered to Folkestone-based Kent Cams a few months ago has cut cycle times by two thirds and increased accuracy through one-hit machining.

Specialising in the manufacture of camshafts for customers that include Ferrari, Aston Martin and Cosworth, Kent Cams takes a data-set of points and reverse-engineers this information into a cam profile that will deliver maximum performance.

After deciding to increase its capacity, the company looked in detail at a number of machines and their ability to drill deep holes. Managing director Andy Burns says: “Firstly, we needed a machine capable of turning shafts up to 1m long. We also needed a C axis, a Y axis and live tooling to cut the machined details, plus the ability to drill deep holes. A visual examination of the build quality of the DMG Mori NLX 2500 showed that it had the strength in its castings and the attention to detail in its construction that we were looking for.

“Moreover, it had an option for 70-bar coolant, which we needed for swarf clearance during deep-hole drilling, and its seals could manage this as standard, whereas other machines we looked at would need uprated seals to cope with increased pressure. The rigidity of the turret and its built-in motor combined with the high-pressure coolant has enabled us to drill far deeper than we expected — and resulted in longer tool life.”

For cutting the machined elements on the camshaft, the NLX 2500 has a ±50mm stroke in the Y axis, which is more than enough for the largest cam profiles. “Cutting the complete cam in one operation gives us much greater accuracy, as everything comes off one datum, and we can easily achieve angular tolerances of 6sec. The NLX 2500 has cut camshaft machining times from 3hr to 1hr.”