High-speed high-power milling

Posted on 30 Jan 2014. Edited by: John Hunter. Read 5673 times.

#engineering #tooling #mfg #milling Two new Scharmann Ecospeed machining centres are now available from Birmingham-based Starrag UK Ltd

(www.starrag.com). These extend the range of products that use the manufacturer’s Sprint Z3 parallel kinematic head for high rates of metal removal. For example, they can transform a 4-tonne aluminium billet into a complex 120kg structural part in less than 20hr; that is equivalent to a cutting volume of 8,000cm3/min.

Both the new models — the Ecospeed 20210 and the Ecospeed F 1040 — feature 120kW 30,000rev/min spindle motors and have the option of a C axis that allows the use of automatic interchangeable angular milling heads. Of column-type design, the Ecospeed 20210 has X- and Y-axis travels of 28.1 and 2.2m respectively, while the stationary-crossbeam Ecospeed F 1040 can handle pallets up to 1 x 4m.

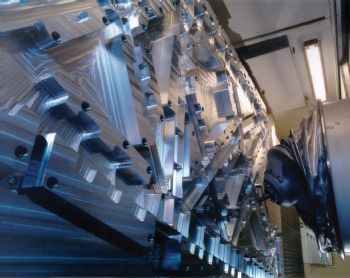

The Sprint Z3 machining head uses three parallel-linear-axis drives mounted radially — and equi-spaced — in the headstock. The spindle platform is connected to each drive via rigid levers with pivots at each end and a ball joint at the other. Appropriate movement of these axes allows the spindle to move in a straight line in Z or any path within a spherical cone of ±40deg (at a maximum of 80deg/sec).