Specialist plastic-flow analysis software is performing a significant role for a leading UK tool and mouldings manufacturer producing more than 400 pre-proven tools a year.

Moreover, the cost of the software was recovered within the first month of its use.

Formaplex (

www.formaplex.com) designs and manufactures aluminium and steel injection mould tools for the automotive, motor-sport and aerospace industries; it also makes low-volume finished moulded components such as brackets and fixings, bumper assemblies and instrument panels.

In addition, it supplies composite tooling and components; plus it carries out specialist machining and finishing, which includes painting, flocking and assembly. Formaplex has some 40 CNC machines — both three- and five-axis types — with machining envelopes up to 8 x 6.2 x 2m, along with 11 injection moulding presses with capacities ranging from 55 to 3,500 tonnes.

Technical director Adrian Chapman says Visi Flow software (

www.visicadcam.com) is vital in ensuring the long-lasting integrity of the company’s mould tools, as its injection simulation ensures cost-effective and reliable designs, along with optimum moulding conditions resulting from well-balanced runners and symmetrical filling patterns.

“Aluminium moulds in particular can be damaged if filled from the wrong position in the wrong sequence, or by using

excessive pressure with an inadequate clamping tonnage. It’s all too easy to blow the mould and damage the parting faces. However, Visi Flow shows us all potential manufacturing issues — such as welding lines, air traps and the best gate location — before the mould is trialled.

“We can quickly analyse where the pressure is going to be too high, whether the material will freeze too quickly, if we need to have more than one gate — and whether the gates are in the right place. Once we’ve analysed and understood exactly what we need to do, we can advise the customer on any necessary changes, such as part-thickness modification, changing the material or re-engineering the component.”

Initial studies of moulded features and ‘draft check’ analysis tell Mr Chapman all he needs to know to complete his initial Design for Manufacturability (DFM) work. He then carries out initial fill studies, with Visi Flow providing the same level of control over injecting molten polymer into the mould cavity as is available on the moulding machine.

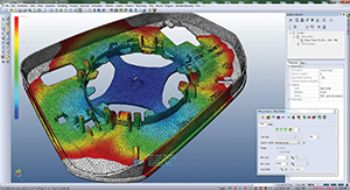

The simulation provides the ability to forecast and visualise how a component will be filled by the plastic melt front, making it possible to identify any potential aesthetic issues. The software provides a number of analytical tools that allow the investigation of moulding variables, including pressure, temperature, shear stress, frozen skin, fibre orientation, clamping force and many others.

“With Visi Flow, I can quickly analyse the customer CAD data to verify moulding feasibility by checking for draft conditions and undercut features; it then shows the capability of successfully moulding the required plastic part. We use the part-splitting tools to create parting faces, thereby allowing us to quickly design the main core and cavity block. Once we have those finalised, we model the sliders, lifters and any other small components and incorporate them into the mould tool.

“With Visi, we can simulate the mould kinematics and correct any issues before we start cutting metal. It gives a very clear indication of all areas where problems could arise. We can give our customers full and accurate information regarding the development of their mould tools.”

Formaplex operates from 150,000ft2 of factory space at three ‘state of the art’ sites in Hampshire — and it is expanding this year with a 120,000ft2 purpose-built facility. The company’s Specialist Engineering division supports the metrology department, where moulded components are inspected and measured using the latest CMM technology. Formaplex designs and manufactures bespoke fixtures for the inspection process, under the guidance of Specialist Engineering manager Grant Keates.

Visi also plays a key role in this process, ensuring absolute accuracy and repeatable tolerances. Fixtures are designed by importing the native CAD model into Visi and creating the fixture around the critical points of the component. “The CAD data can come from our customers in a range of formats, but Visi handles them all seamlessly.

The next step is to send the finished CAD data of the fixture to the shopfloor, where Visi Machining’s high-speed milling techniques and built-in smoothing algorithms create ‘intelligent’ three- and five-axis tool-paths.”

Summing up the company’s use of Visi, Mr Chapman says: “The software provides us with key information at the design stage, and it supports the complete mould process. A conservative estimate is that within the first month of using Visi Flow to analyse the correct filling pattern and optimise our process parameters, we saved the cost of the software by avoiding down-time, repairs, wasted tool-making and setting time — and through reduced material costs.”