Canada-based

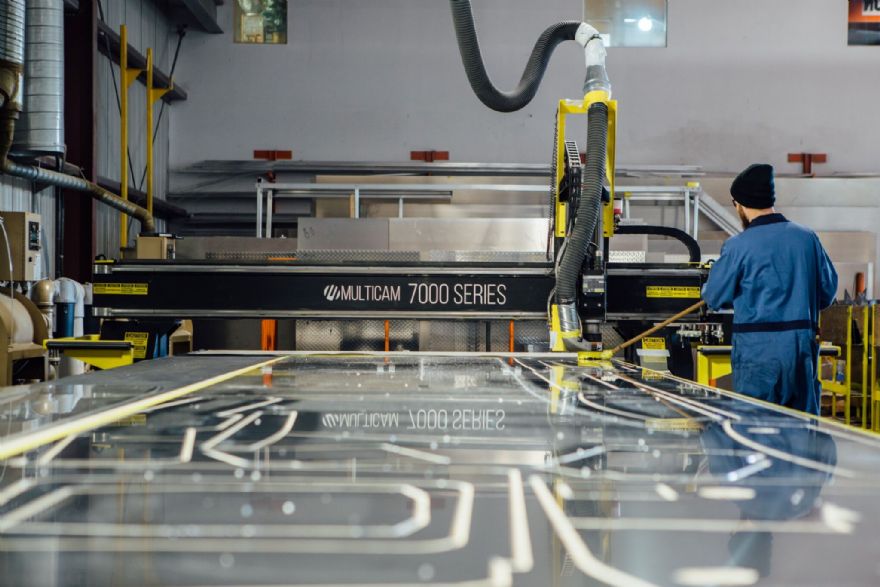

Kingfisher Boats has manufactured a range of welded aluminium hull boats since 1959. Due to the fluctuating cost of aluminium, the company researched the market for better software, eventually purchasing JetCAM expert CAD/CAM with high-performance nesting (HPN) and a single postprocessor to drive an ESAB plasma cutter in 2008. A Multicam router post was added in 2015, and a second in 2017, with the ESAB being retired in 2024.

Kingfisher Boats had already been using the software for 16 years when product development technologist Bob Hackl took over the management of the software in January 2024, after previously operating the CNC routers. Despite very little experience with CAD/CAM or nesting software he was able to get up-and-running very quickly. He said: “I found it very easy to learn the basics of JetCAM.”

When performing ‘CAD Import’, JetCAM’s ‘Single Component Automatic Processing’ (SCAP) was able to provide a fast and automated process of importing DWGs and applying automatic tooling for both routers.

Mr Hackl explained: “I just enter the source and destination locations, plus part thickness and click Go." Entire directories can then be processed without further user input. JetCAM Expert stores tooling at the component level on a per-machine basis, meaning that parts can be tooled for multiple machines automatically, and are then instantly available for nesting and NC code generation on any machine.

‘Automatic Tooling’ takes care of all routing without any required user input during CAD import. Multi-depth routing, scribing, partial depth cutting and corner pocketing are all configured once and then applied automatically with automatic tooling.”

He added: “With the instability of raw material prices and global price wars, prices fluctuated between $1,600 and over $4,000 per tonne between 2020 and 2022. Kingfisher Boats has been able to take advantage of HPN’s time-based approach to nesting. This allows Mr Hackl to choose whether to let the nester try for the best efficiency, or opt for speed. He said: “HPN is set to run for 5min by default, but I will often stop it in under 3min, as nests are usually very efficient by then.”

Static or dynamic nestingThe company also benefits from the flexibility of being able to perform static or dynamic nesting. As many parts are repeated, static nests that have been optimally produced using HPN offer good material efficiency. However, being able to create a nest that either has a mix of orders or perhaps including parts scrapped further on in production gives Kingfisher complete flexibility. Mr Hackl said: “We generally static nest, but if we have to deal with significant changes then it's no issue to create a new nest dynamically.”

When Mr Hackl transitioned from CNC operator to programmer, he had little experience of nesting. However, in addition to the system being easy to learn, he also took advantage of JetCAM's online university, which includes hundreds of free to access tutorial videos. Having viewed over 90 videos, he remarked: “I found the JetCAM University extremely informative. Local support by their local reseller,

NestOne Solutions, has also been excellent, with all questions answered quickly, positively and fully. NestOne have always been very helpful, with all questions answered quickly and satisfactorily.”

With over 75 years of manufacturing expertise behind it, Kingfisher is confident that JetCAM is the right partner to take the company forward. Mr Hackl concluded: “JetCAM is easy to learn, especially using the university. It is a powerful program with solid support and I have never had a problem that it couldn’t help me with.”