At

ElringKlinger AG, the transition from development to series production is a critical phase — one that demands precision, speed, and cost-efficiency. For Daniel Weller, an expert in joining technology within the company’s Battery Technology division, the challenge lies in developing and testing production processes on pre-series machines and then transferring them flawlessly to one of ElringKlinger’s 40 global production sites. He said: “Every day of development work costs money that only flows when the series is up and running. We have to keep the ramp-up phase as short as possible.”

During a recent visit to the

Trumpf Laser Application Centre in Ditzingen, near Stuttgart, Mr Weller was introduced to EasyModel AI, an artificial intelligence (AI) based programming wizard still in its final stages of development. He reflected: “It was clear to me that it could be of interest to us.” As luck would have it, not long after, ElringKlinger received an order for the series production of an innovative cell contacting system — an ideal use case for EasyModel AI.

ElringKlinger AG is a global supplier to the automotive industry, providing solutions for all types of drives. Among its key products are cell contacting systems (CCS) for electric vehicles (EVs), which connect individual battery cells into a single unit and transmit vital data such as voltage and temperature to the battery management system. These components must be manufactured with zero defects. Traditionally, CCSs used in module-to-pack battery designs are around 600mm long and require 10 to 20 weld points, each needing precise laser detection and joining.

No small featHowever, the industry is continually shifting. Mr Weller explained: “In the next generation of vehicles, cell-to-chassis designs will be used. The battery forms part of the car body and the sub-floor of the vehicle — this saves space and weight, increases energy density and simplifies the design — but it also requires more precise production.” The new CCS components are nearly 2m long, just 20mm thick, and feature around 50 weld points. He added: “Developing a stable and efficient series production process with short cycle times is no small feat.”

Previously, ElringKlinger relied on Trumpf’s VisionLine Detect image processing system, which required position-dependent exposure adjustments to detect weld points. This process was highly manual and iterative, needing individual calibration for each component position. Mr Weller said: “The models generated by EasyModel AI and the resulting filters transformed this highly manual process adjustment into a simple standard procedure.”

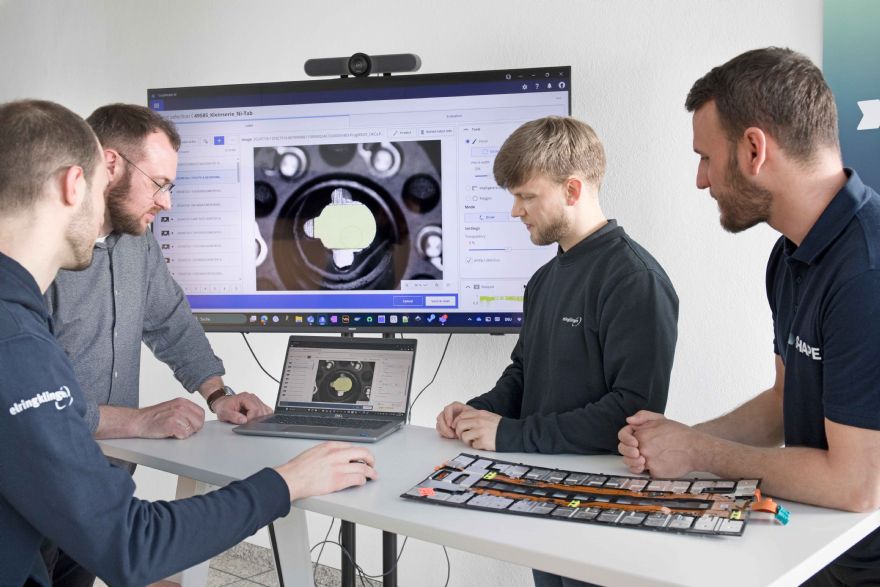

EasyModel AI is a zero-code tool that allows users to create and train image-based AI models without programming knowledge. Mr Weller explained: “As before, we use VisionLine Detect to record images of the component areas where weld points are located. We load these into the EasyModel AI tool via drag and drop.” After creating a project, weld points are marked directly on the images using a tablet-like interface. The AI then evaluates the data and generates a model that can be refined step by step.

Edge-detection algorithmsJust a few training images are enough to create a functional AI mode. Once the model meets expectations, it is integrated into the production line and tested on real components. The AI filter option for VisionLine Detect enhances feature detection, distinguishing relevant image areas from fixtures, dirt or reflections. Mr Weller said: “The difference between VisionLine Detect with and without an AI filter is very clear. The AI filter binarises the image — displaying the detected component in white and the surrounding areas in black. This allows the edge-detection algorithms to easily identify the welding area.”

Activating the EasyModel AI and AI filter extension for VisionLine Detect was very straightforward. Mr Weller reflected: “Trumpf experts guided us through the process steps during commissioning. After an hour or two, we had our first result.” The simplicity of the system is a major advantage. “Even if the series is already running, there will be a need for adjustments. That is when our colleagues at the locations will have to step in. So it is good that the system works according to the ‘what-you-see-is-what-you-get’ principle. This is easy to understand even for non programmers.”

In pre-series development, time is of the essence. Mr Weller said: “EasyModel AI speeds up the process significantly. We now only need hours to achieve good results rather than days, and retraining also saves a lot of time.” The ease-of-use has also made the technology viable for small series and prototyping — areas previously considered too time-consuming. Now, Mr Weller and his team are exploring further applications across the company. He concluded: “I see great potential everywhere where we have to detect many weld points within tight tolerances — it is simply quicker with AI.”