GibbsCAM

GibbsCAM, a recognised leader in CAD/CAM solutions for production machining, has unveiled its latest release — GibbsCAM 2026 — marking a significant milestone in the evolution of computer-aided manufacturing. With a focus on speed, precision, and enterprise-wide accessibility, this release introduces a re-engineered ‘Advanced 3-D Machining’ engine, a new ‘GibbsCAM Viewer’, and a host of enhancements across turning, multi-axis machining, and tool management.

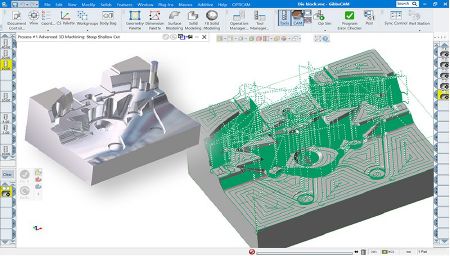

At the core of GibbsCAM 2026 is the new ‘Advanced 3D Machining’ engine, a complete architectural overhaul designed to deliver faster toolpath calculations and smoother machining results. The engine generates more predictable paths, significantly improving surface quality and reducing the need for secondary finishing. Despite the deep technical changes, GibbsCAM has preserved its familiar interface, allowing users to adopt the new capabilities without retraining.

Thorsten Strauß, president of GibbsCAM, said: “With GibbsCAM 2026, we are taking another important step forward in delivering best-in-class solutions and services to our customers worldwide. The new Advanced 3D Machining engine, combined with our continued focus on usability and intelligent automation, represents not only a major achievement today but also a strong foundation for the future of CAM.”

Another highlight is the GibbsCAM Viewer, a read-only tool that enables company-wide access to CAM data. Operators, managers, and quality teams can now inspect parts, verify geometry, and analyse toolpaths without the risk of altering NC code. This new capability enhances communication across departments and ensures that everyone involved in the production process has the information they need to run parts with confidence.

More intuitive workflowTurning operations also receive a major upgrade. ‘Variable-B Turning’ now features a more intuitive workflow, allowing programmers to define tool angles directly along the cut path using control points. This interactive approach improves accuracy and reduces setup time. For advanced turning tools like Sandvik Coromant’s CoroTurn Prime inserts, GibbsCAM 2026 introduces smarter toolpath generation that intelligently calculates material engagement, maximising insert geometry while maintaining safety and consistency.

Pictured left: the new Advanced 3D Machining engine in GibbsCAM 2026 delivers faster toolpath generation and improved surface quality with the same familiar interface

Pictured left: the new Advanced 3D Machining engine in GibbsCAM 2026 delivers faster toolpath generation and improved surface quality with the same familiar interfaceTool management has been re-imagined with the introduction of the ‘Tool Usage Reporter’, a manager-style interface that tracks every operation linked to a selected tool. Users can quickly identify, select, or remove tool-linked operations, streamlining the programming process. A redesigned ‘Tool List View’ offers a spreadsheet-style layout with column labels and filtering by tool group, making it easier to organise and edit tools in complex projects.

Optimised cycle efficiencyMulti-axis and five-axis machining capabilities have been expanded with new tilting strategies and improved AutoTilt functionality. The system now supports bullnose tools and introduces two new tilt strategies — ‘Tilted into Plane’ and ‘Tilt Tool’ in a ‘User-defined Plane’ — giving programmers precise control over tool orientation. Multiblade machining also sees improvements, including a new ‘Edge Finishing’ strategy and expanded support for various tool types. These enhancements reduce non-cutting time and optimise cycle efficiency across intricate geometries.

Usability and simulation enhancements further elevate the user experience. Programmers can now scale solids and rotate geometry out of plane with ease, measure minimum and maximum distances for inspection, and benefit from more accurate stock definitions. Simulation playback reflects actual machining time and includes metallic rendering for improved visual clarity. Undo/Redo history navigation adds flexibility to the design process, making GibbsCAM 2026 more intuitive and reliable than ever.

The release is bolstered by new partner technologies that extend GibbsCAM’s capabilities. ‘Vericut Optimizer’ dynamically adjusts feed rates to maintain ideal chip thickness, resulting in faster cycle times and longer tool life. ‘ToolManageriQ’ offers centralised management of tools, holders, and fixtures via a robust SQL database, improving collaboration and data reliability.

‘CloudNC CAM Assist’ introduces AI-powered automation for CNC programming, capable of generating complete three-axis and 3+2 toolpaths directly from GibbsCAM session data — dramatically reducing programming time and helping manufacturers address the skilled labour shortage. GibbsCAM 2026 is not just an upgrade — it represents a strategic leap forward for manufacturers seeking greater efficiency, precision, and collaboration in CNC programming.