London-based Siemens (

www.siemens.com) has released the latest version of Solid Edge software, a portfolio of software tools designed to aid all aspects of the product development process, including mechanical and electrical design, simulation, manufacturing, technical documentation, and data management.

Moreover, Solid Edge 2019 introduces Solid Edge CAM Pro, a system that uses the latest machining technology to program CNC machine tools.

This offers capabilities such as adaptive and feature-based machining, ‘smart’ pencil milling, and enhanced roughing routines. Tool-paths are associative to the Solid Edge parts and assemblies, so they can be quickly updated to incorporate any design changes.

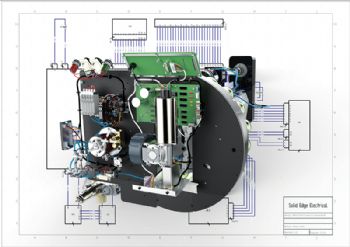

Solid Edge 2019 also adds electrical and PCB design technologies, new requirements-management capabilities, integrated simulation analysis, the latest tools for subtractive and additive manufacturing, and free cloud-based project collaboration.

The expanded portfolio is said to make it even easier for customers to take advantage of the end-to-end digital twin.

Solid Edge Wiring Design provides design and simulation tools for creating wiring diagrams and the verification of electrical systems.

Furthermore, Solid Edge Harness Design adds intuitive harness and form-board design tools with automated part selection, design validation and manufacturing report generation, while Solid Edge PCB Design ‘accelerates’ schematic capture and PCB layout (it is integrated with mechanical design to help reduce errors).

The latest release of Solid Edge also includes new modular plant design capabilities.

Providing 2-D flow diagram and symbol support for P&ID (piping and instrumentation diagram) creation, Solid Edge P&ID Design supports “strict governing requirements” for the design of plants.

Combined with Solid Edge Piping Design capabilities, these new features can help to reduce errors and aid piping design in industries such as oil and gas.

New additive-manufacturing capabilities include better control of shapes, weight and strength — and specific factors of safety — to help customers develop designs that were not possible previously.

Solid Edge also automates print preparation, including multi-colour and multi-material printing capability, which reduces bill-of-material size and parts inventory — and dependency on costly manufacturing equipment.