A sub-contract motor-sport machine shop, Alitech Precision Ltd is developing rapidly thanks to an aggressive investment programme.

Since being formed just over three years ago, the Silverstone-based company has purchased a variety of equipment, including a simultaneous five-axis Spinner machining centre, three Haas machining centres, Open Mind CAM software, and cutting tools from Tamworth-based Industrial Tooling Corporation (ITC) (

www.itc-ltd.co.uk).

The relationship between Alitech and ITC started just over 18 months ago, when the Alitech team encountered tool life and performance issues with an existing tooling vendor when machining steel.

Alitech Precision’s senior five-axis programmer, Charlie Watts, said: “ITC engineer Gary Bambrick came in and trialled the four-flute 4081 Cyber series of solid-carbide end mills; the results were remarkable.

“After undertaking so many trials with a multitude of cutting-tool suppliers, we were always going to be a little sceptical of advice from tooling engineers.

“However, Mr Bambrick optimised the speed and feed parameters of the 4081 cutters with impressive results.”

Alitech has since widely implemented the ITC 4081 cutters for steel and titanium parts, purchasing 4, 6, 8, 10, 12, 16 and 20mm-diameter end mills.

The 4081 cutters are AlTiN-coated four-flute solid-carbide end mills with a ‘harmonic’ flute geometry that provides particularly effective swarf evacuation, thanks to the unequal spacing on right-hand-helix.

Also contributing to good cutting performance is the small corner radius, “innovative geometry design” and sub-micron grade carbide.

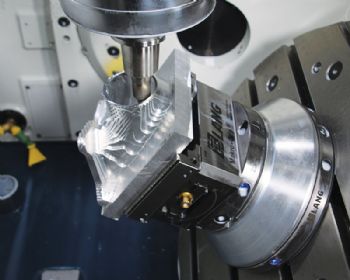

Most of the projects undertaken by Alitech involve the complex simultaneous five-axis machining of parts such as billet inlet manifolds, valve seats, cylinder-head inlet ports and billet turbo manifolds.

Reaching deep into ports is a complex challenge for the five-axis machine tool’s kinematics, the CAM software, the cutting tools and tool-holding.

For much of this work, Alitech is using ITC 4101-series ‘lollipop’ end mills, as these allow the company to reach surfaces around corners and deep inside manifold ports.

Commenting on the daily challenges at Alitech, managing director Darren Cudd said: “We recently machined a billet turbo manifold for a motor-sport customer that required two 40mm-diameter oval-shaped and curved ports some 200mm deep.

“We used an 8mm-diameter ITC lollipop cutter that was ‘necked’ to 5mm and protruded 70mm out of a slim 80mm-long heat-shrink tool-holder extension with a 75mm long back end.

“The first concern when machining inside deep bores is collision detection. The second issue on this job was whether we would achieve the required level of surface finish with such a long tool protrusion.

“However, the rigidity and geometry of the ITC lollipop tools ensured that we achieved the necessary surface finish, even though we were using highly productive speeds and feeds.”

Alitech has recently been collaborating with a high-performance tuning company to increase the power of an Audi RS6 to more than 1,000bhp. To help achieve this level of power, it manufactured new intake manifolds that are key components in an intercooler conversion.

These were machined on its five-axis Spinner, using ITC 4101-series 12mm-diameter lollipop tools.

Mr Cudd said: “We used these tools for ‘back cutting’ around corners on the 6082 grade aluminium manifold ports. The shank of the 12mm-diameter tool was necked to 8mm in diameter to allow maximum reach while ensuring sufficient rigidity for optimal surface finishes.

“We ran the spindle of our five-axis Spinner at 12,000rev/min with an 8m/min feed and a 0.5mm step-over. Machining at these parameters generated the ideal balance of material removal, surface finish and tool life.

“In fact, we are using the ITC lollipop tools for all our aluminium porting, and the 12mm tool we are using at present has been running for over five months.”